Gukora neza

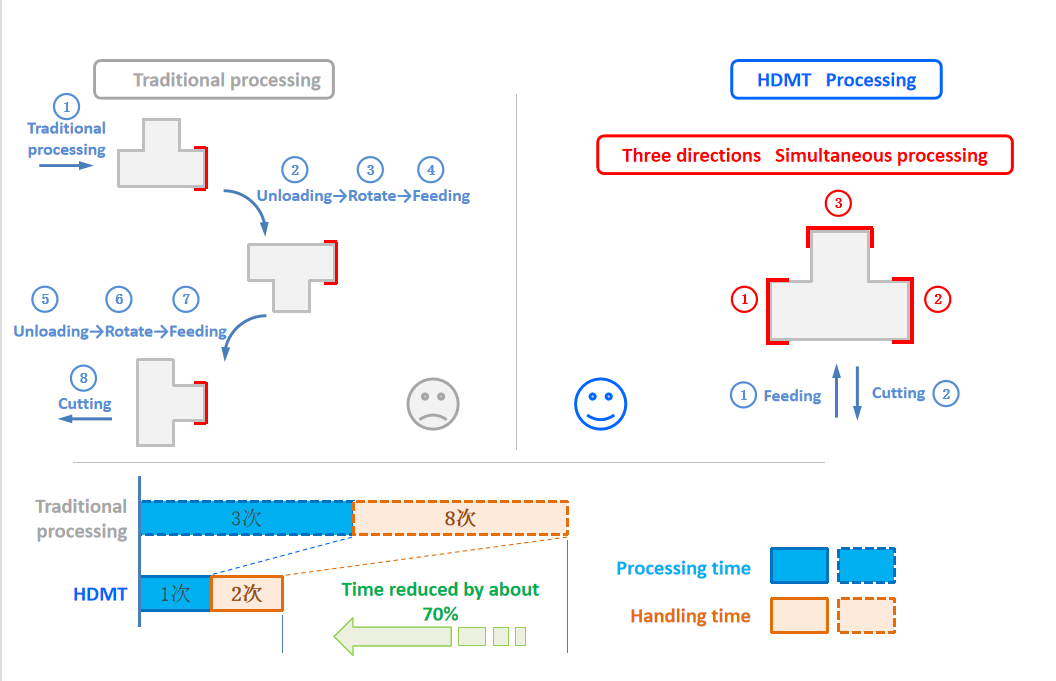

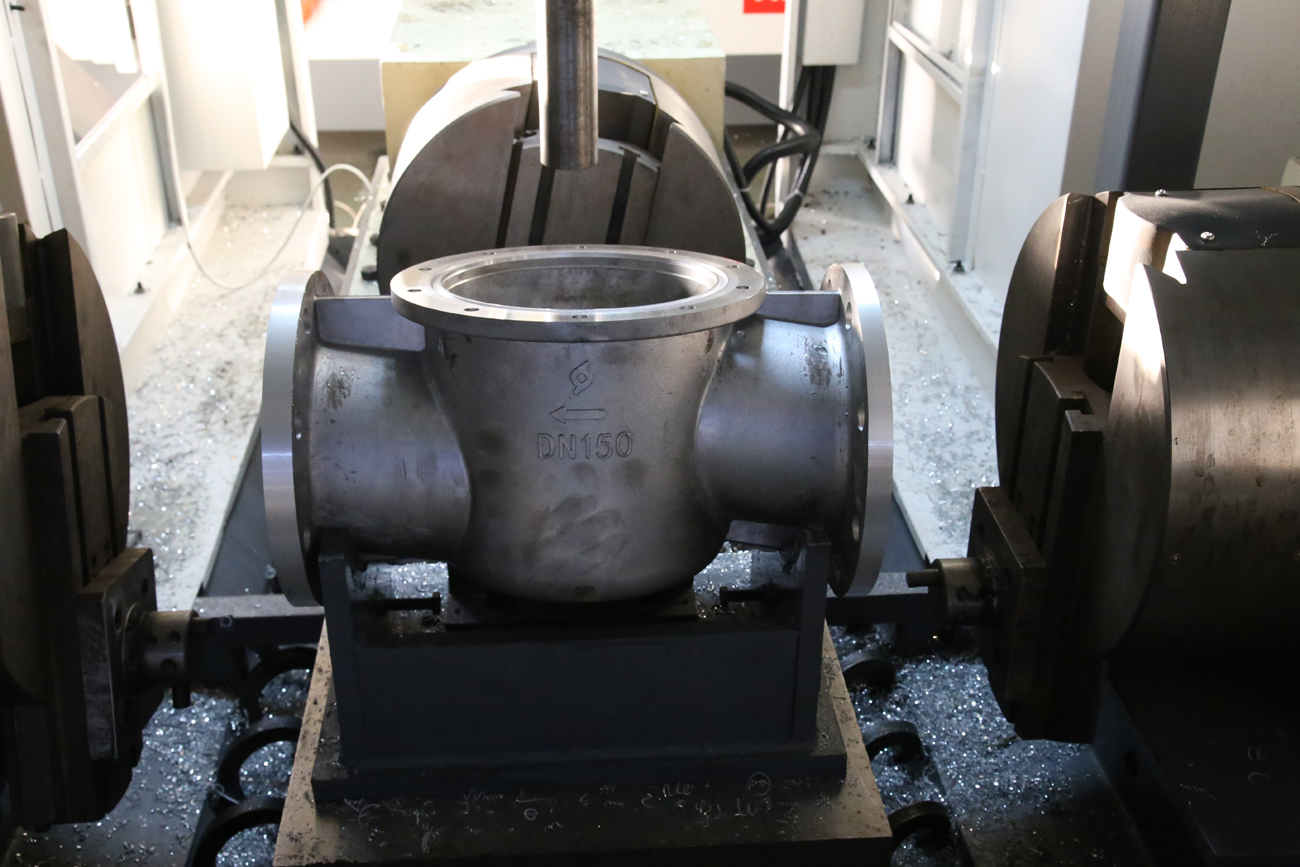

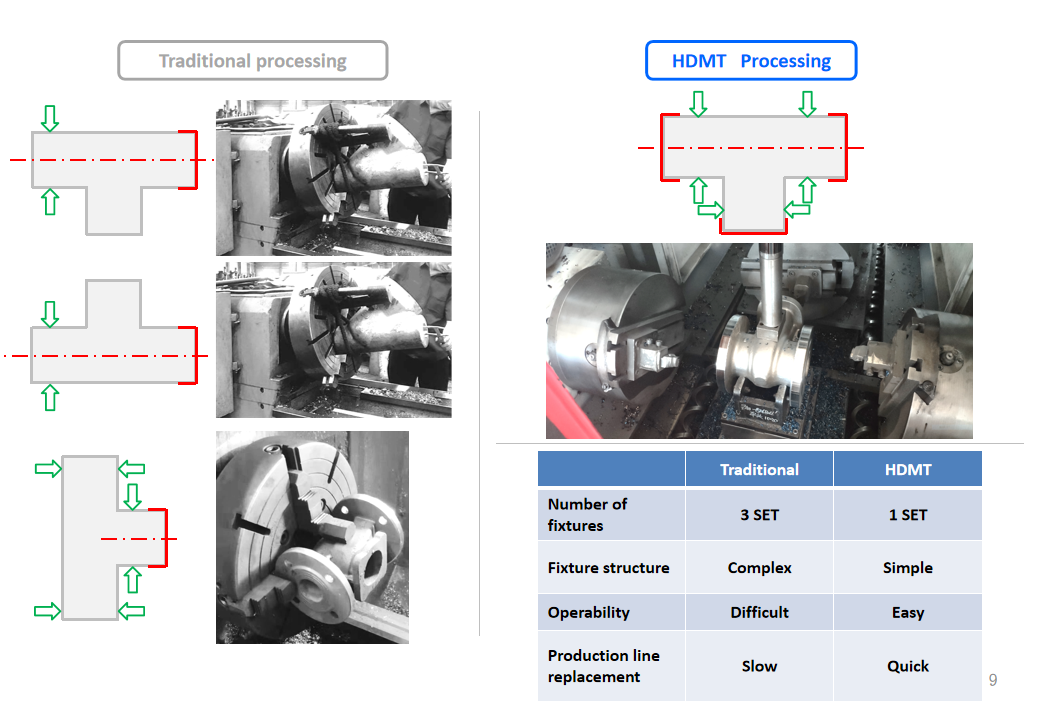

Imashini gakondo itunganya valve ikeneye gutunganya igihangano inshuro eshatu, kandi igomba gufatanwa no gutunganywa inshuro eshatu inshuro eshatu, mugiheHDMT CNC Imashini eshatu zihindura isuraIrashobora gutunganya amasura atatu icyarimwe, kandi urupapuro rwakazi rushobora kurangizwa no gupakira no gupakurura. Gutunganya bizigama cyane igihe cyo gutunganya.

Igishoro

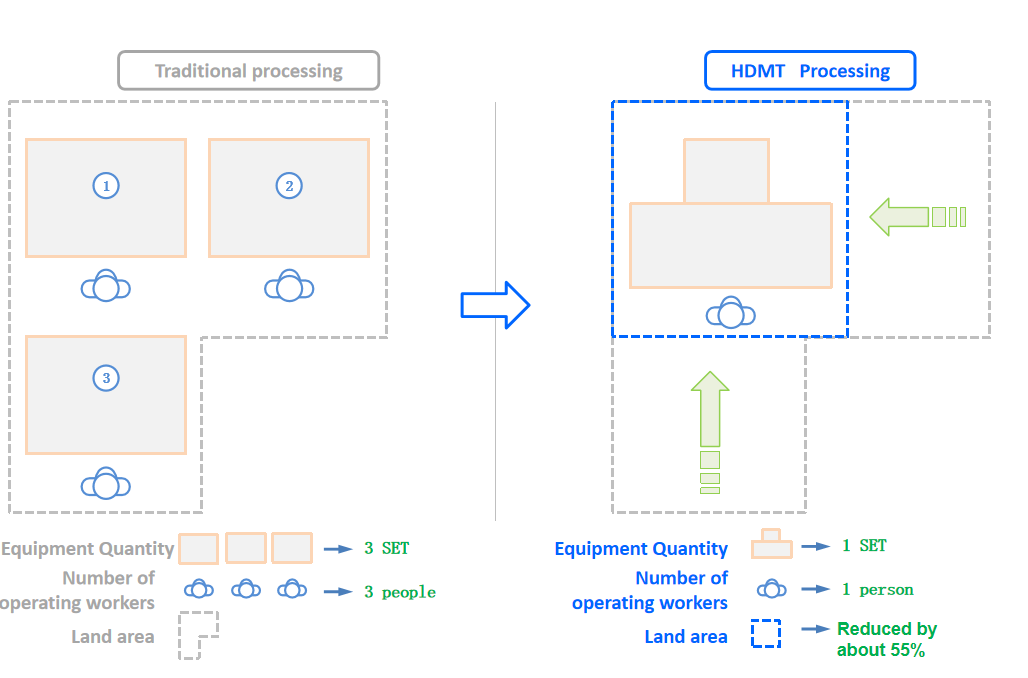

Uburyo bwa gakondo bwo gutunganya imashini ya valve isaba imashini eshatu kumpande eshatu, kandi buri mashini nayo igomba kuba ifite ibikoresho bijyanye nabakozi, bikubiyemo ahantu hanini kandi bihenze cyane.HDMT CNC Imashini eshatu zihindura isuraikeneye gusa imashini imwe yo gutunganya impande eshatu. Ikeneye gusa kuba ifite imashini imwe yimashini, igabanya cyane umwanya wimashini hamwe nigiciro cyabakozi.

Gutandukanya imashini

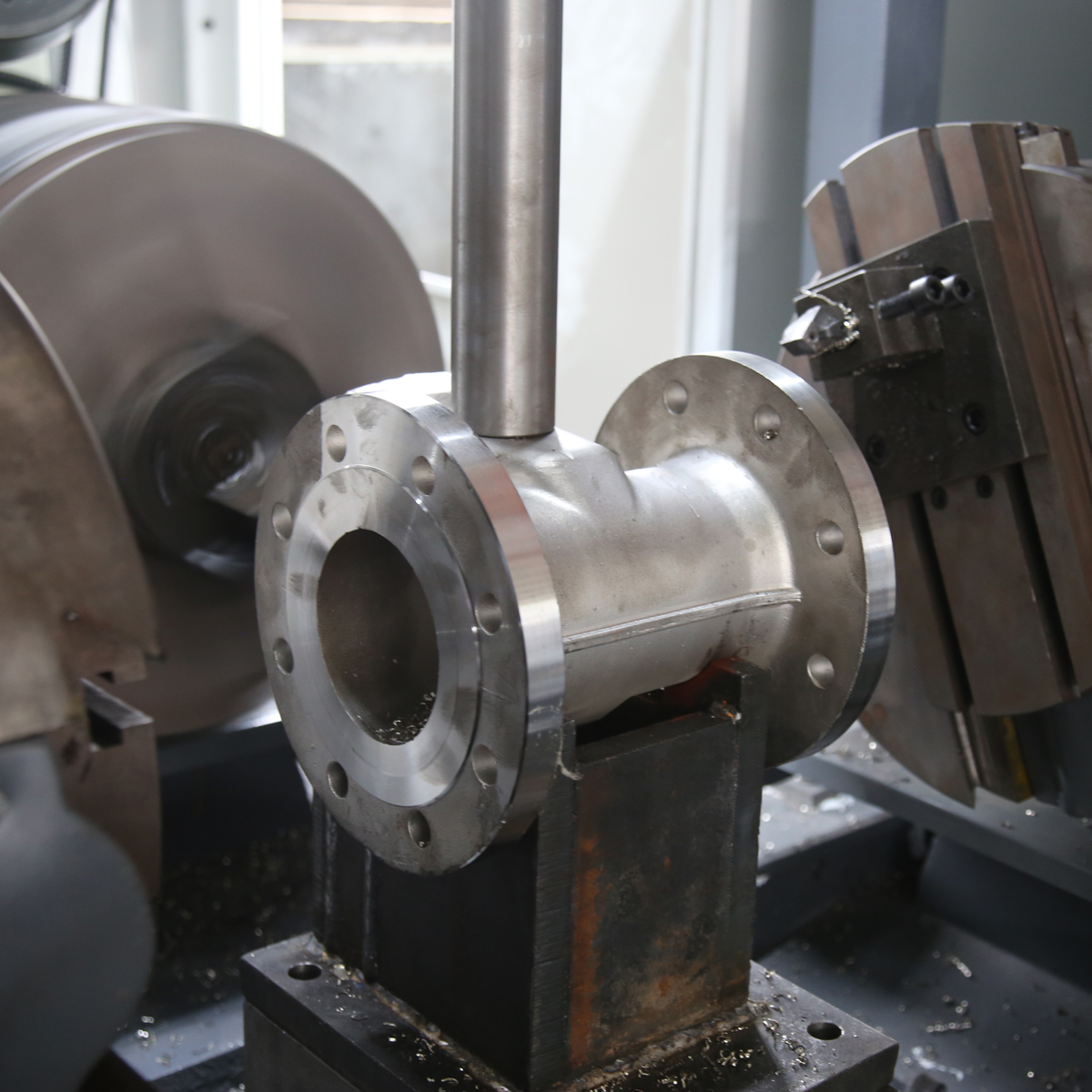

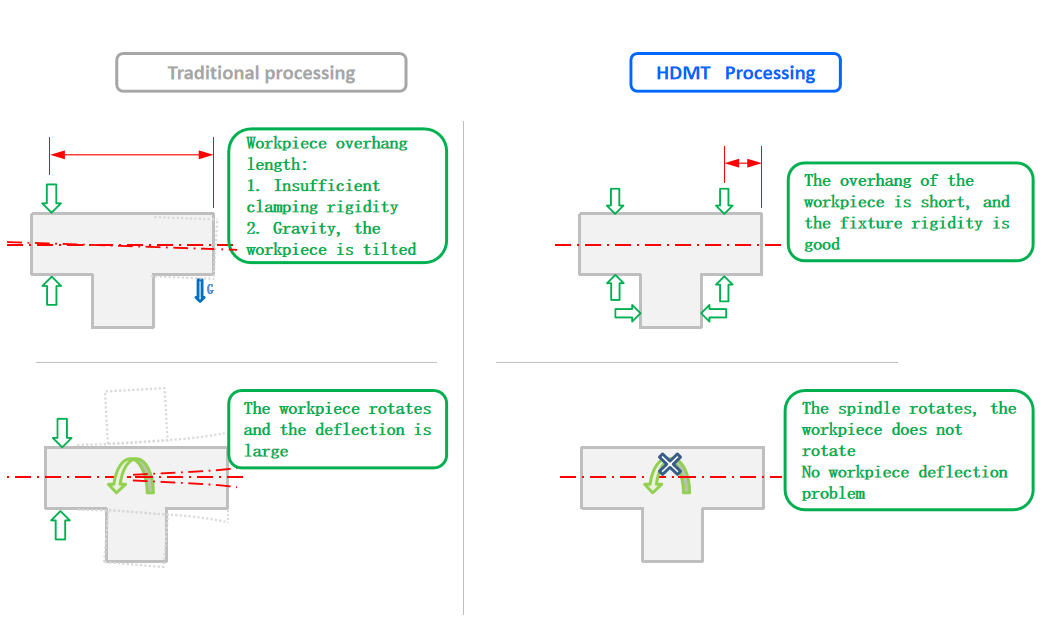

Iyo imashini gakondo itunganya valve ifata igice cyakazi, biroroshye gutera ihinduka ryigice cyakazi, igice cyakazi kirazunguruka, kandi gutandukana ni binini, bigira ingaruka kumikorere ya valve. Kurenza urugero rwakazi ni mugufi mugihe igihangano cyafashweHDMT CNC Imashini eshatu zihindura isura.

Imiterere

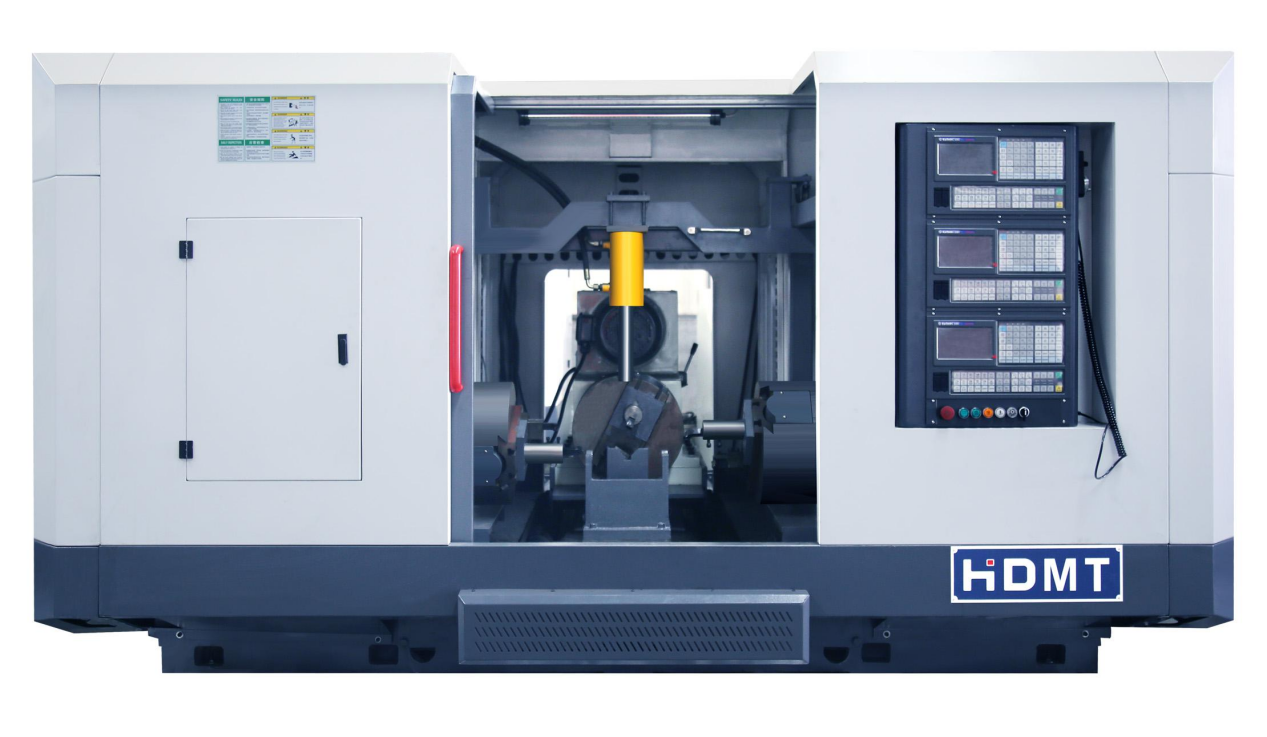

Imashini gakondo itunganya imashini ya valve iragoye cyane, kandi ibice bitatu bitandukanye birakenewe mumaso atatu, bigoye gukora kandi ntibyoroshye gukoresha.HDMT CNC Imashini eshatu zihindura isurafixture ikeneye gusa seti imwe, hamwe nuburyo bworoshye nibikorwa byoroshye.

Guhindagurika

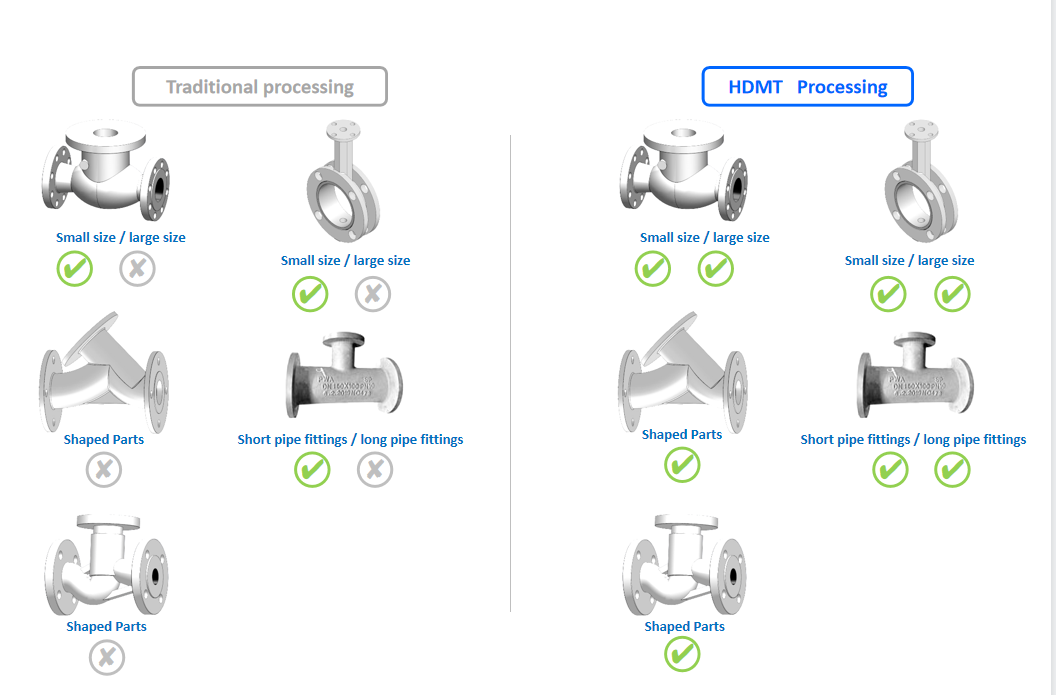

Imashini gakondo itunganya valve ifite aho igarukira mugihe itunganya valve. Niba utegura ikintu gito, ntushobora gukora valve nini yihariye. Niba wateguye umuyoboro mugufi ubereye, ntushobora gukora valve ndende. Imyanya idasanzwe idasanzwe ntabwo ifite ubushobozi bwo gutunganya.HDMT CNC Imashini eshatu zihindura isurairashobora gutunganywa utitaye ko ari nini cyangwa nto, ndende cyangwa ngufi, idasanzwe-isanzwe.

Igihe cyo kohereza: Ukwakira-14-2021