Imashini isanzweni ubwoko bwimashini ya lathe idafite igenzura ariko nigitabo. Ifite intera nini yo gukata kandi irashobora gutunganya umwobo w'imbere, uruziga rwo hanze, isura yanyuma, hejuru yikurikiranya, gushushanya, guswera, insinga hamwe nubuso butandukanye bwa arc. Ubwiherero busanzwe nubwoko bukoreshwa cyane bwimashini ya lathe, bingana na 65% byumubare wimashini ya lathe. Bitwa imisarani itambitse kuko izunguruka zashyizwe muburyo butambitse.

Imikorere:

1.

2. Urudodo rwibipimo, urudodo rwa santimetero, umugozi wa modular, gukata urudodo;

3. Kurasa no guhinduranya ibyuma birebire;

4. Gucukura, kurambirana, gukubita no gutobora;

5. Guhindura ukuboko kw'ibumoso no guhindukirira ukuboko kw'iburyo;

6. Ndetse no gusya no gusya hamwe no gusya hamwe no gusya.

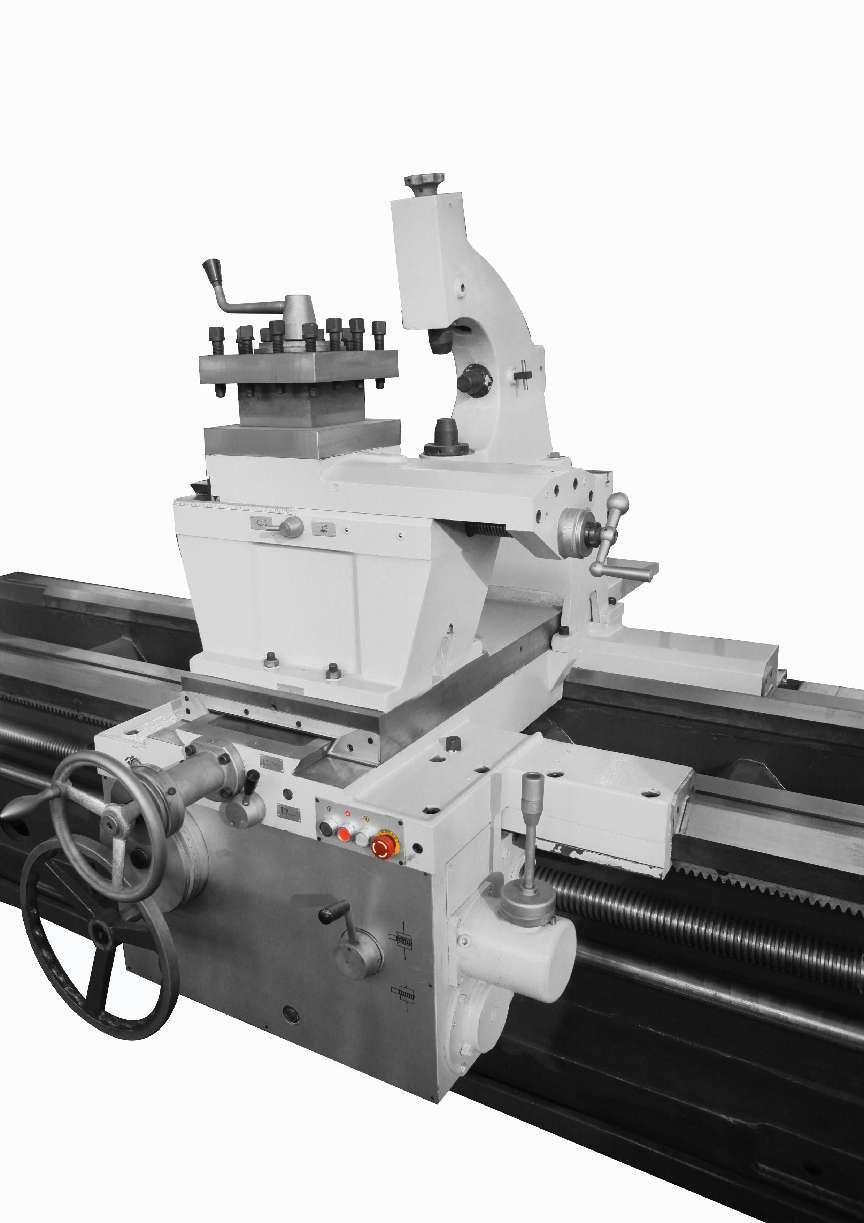

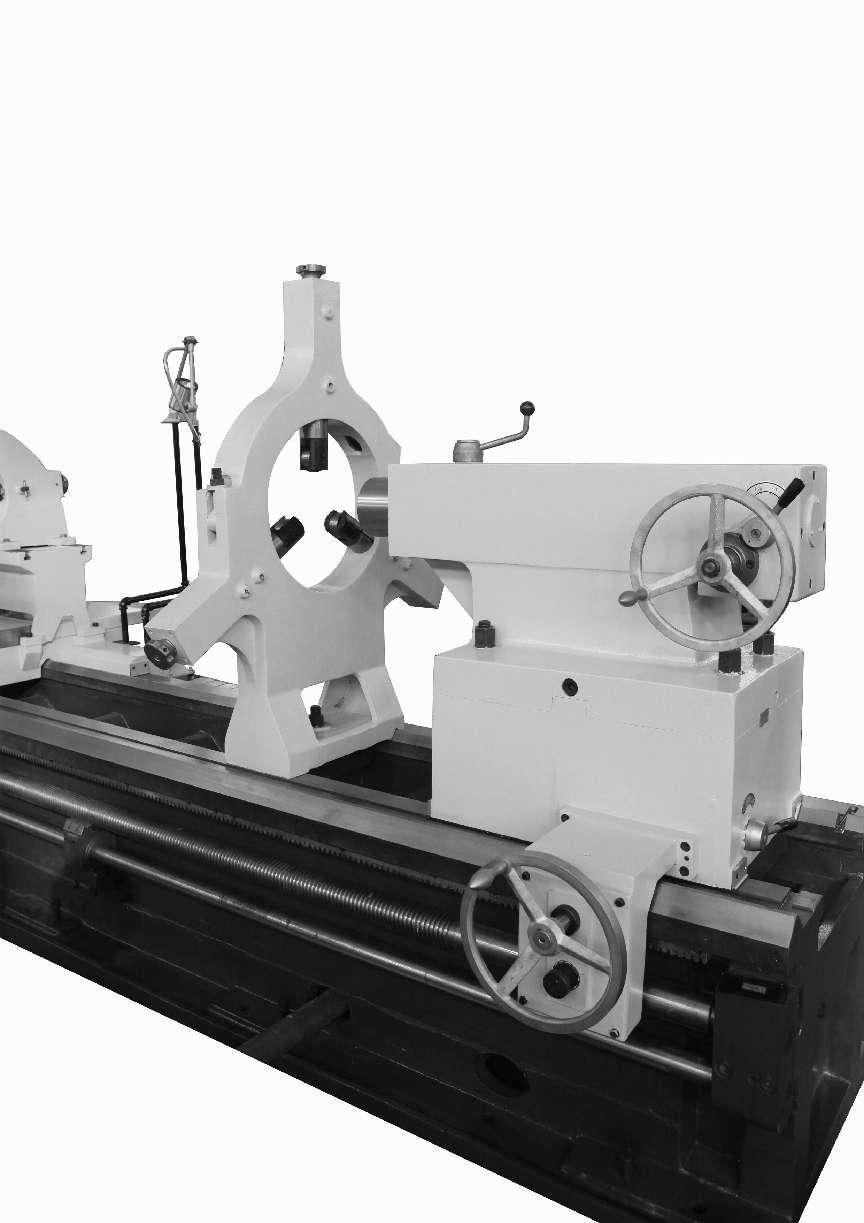

Ibice nyamukuru bigizeimashini zisanzwe: uburiri, umutwe, agasanduku k'ibiryo, iposita y'ibikoresho, ubwikorezi, umurizo, na moteri.

Uburiri: Ibice nyamukuru byaimashini ya lathezashyizwe ku buriri, kugirango zigumane umwanya ugereranije mugihe cyakazi. Imodoka hamwe numurizo byanyerera hejuru yigitanda cyakozwe neza.

Umutwe. Irashobora kubona umuvuduko ukenewe usabwa wo guhinduranya no gusubira inyuma, kandi mugihe kimwe, umutwe wumutwe ugabanya igice cyimbaraga zo kohereza icyerekezo mumasanduku yo kugaburira.Headstock Medium spindle nigice cyingenzi cyumusarani. Ubworoherane bwa spindle kwiruka ku cyerekezo bigira ingaruka ku buryo butaziguye ubuziranenge bwakazi. Iyo kuzenguruka kwukuri kwa spindle kugabanuka, gukoresha agaciro kaigikoresho cyimashinibizagabanuka.

Agasanduku: Agasanduku k'ibiryo gafite uburyo bwo guhindura umuvuduko wo kugaburira. Hindura uburyo bwo guhindura umuvuduko kugirango ubone umubare wibiryo bisabwa cyangwa ikibanza, hanyuma wohereze icyerekezo kubikoresho bifashishije igikoresho cyoroshye cyangwa icyuma cyogosha cyo gukata.Icyuma kiyobora gikoreshwa cyane muguhindura insanganyamatsiko zitandukanye. Iyo uhinduye ubundi buso bwakazi, gusa umugozi woroshye ukoreshwa aho gukoresha icyerekezo.

Ufite ibikoresho: Igikoresho gifitemo kigizwe nibice byinshi byibikoresho byanditse. Igikorwa cyayo ni ugukata igikoresho no gutuma igikoresho kigenda igihe kirekire, kuruhande cyangwa muburyo bunini.

Umurizo: Nka centre yinyuma yo gushyigikira imyanya, irashobora kandi gushyirwaho nibikoresho byo gutunganya umwobo nka myitozo na reamers yo gutunganya umwobo.

ibice

Chuck-jaw chuck (kubikorwa bya silindrike)

bine-jaw chuck (kubikorwa bidasanzwe)

biranga

Ibikoresho bya mashini bisanzweKugira imiterere yoroshye, imikorere yoroshye, diameter nini ya spindle, ikirenge gito, gutunganya ibintu byoroshye, kubungabunga byoroshye, bikwiranye no gutunganya ibyiciro bito no gukora neza.

Igitanda gifata uburiri budasanzwe kandi bukomeye.Imashini ifite pompe yamavuta itandukanye. Igicapo, ibikoresho bifata, hamwe nigitereko birashobora kugenda vuba. Iki gikoresho cyimashini kirashobora gukoresha sisitemu ya GSK cyangwa SIEMENS itabishaka, sisitemu yo kugenzura imibare ya FANUC hamwe nubundi buryo bwo kugenzura imibare ukurikije ibyo uyikoresha asabwa, bishobora gukora umuvuduko mwinshi, gukomeye kandi bihamye, gukata neza neza hamwe na progaramu yoroshye.

Uwitekauhagaritse kandi utambitseibiryo bifata moteri ya AC servo, na pulse encoder ibitekerezo ikoreshwa nkibintu byo gutanga ibitekerezo. Imiyoboro ihagaritse kandi itambitse iyobowe na ultrasonic gukomera no kuvura neza. Gari ya moshi iyobora uburiri yometseho kaseti ya PTFE, kandi coefficient de fraisse ni nto.

Moteri nyamukuru ifata uburyo bwihuse bwo kugenzura umuvuduko wa magnetique no kugenzura voltage, kugirango ukore spindle idafite umuvuduko ukabije.

Uburyo bukoreshwa

1. Kugenzura mbere yo gutangira

1.1 Ongeramo amavuta akwiranye nimbonerahamwe yo gusiga imashini.

1.2 Reba ibikoresho byose byamashanyarazi, gufata, ibice byohereza, kurinda no kugabanya ibikoresho byuzuye, byizewe kandi byoroshye.

1.3 Buri bikoresho bigomba kuba kuri zeru, kandi umukandara ugomba kuba wujuje ibisabwa.

1.4 Ntabwo byemewe kubika ibintu byicyuma kuburiri, kugirango bitangiza uburiri.

1.5 Igikorwa cyo gutunganyirizwa nta byondo n'umucanga, birinda icyondo n'umucanga kugwa muri mashini no kwambara gari ya moshi.

1.6 Mbere yuko urupapuro rwakazi rufunga, hagomba gukorwa igeragezwa ryimodoka yubusa, kandi urupapuro rwakazi rushobora gutwarwa nyuma yo kwemeza ko byose ari ibisanzwe.

2. Uburyo bwo gukora

2.1 Nyuma yakazi kamaze gushyirwaho, tangira pompe yamavuta ubanza kugirango igitutu cyamavuta cyuzuze ibisabwa nigikoresho cyimashini mbere yo gutangira.

2.2 Mugihe uhindura ibikoresho byo guhanahana ibikoresho, mugihe uhindura ibiziga bimanikwa, amashanyarazi agomba guhagarara. Nyuma yo guhindurwa, ibisate byose bigomba gukomera, umugozi ugomba gukurwaho mugihe, kandi igihangano kigomba guhagarikwa kugirango gikore.

2.3 Nyuma yo gupakira no gupakurura urupapuro rwakazi, chuck wrench hamwe nibice bireremba byakazi bigomba guhita bikurwaho.

2.4 Umurizo, igikonjo, nibindi bikoresho byimashini bigomba guhindurwa kumwanya ukwiranye nibikenewe gutunganywa, kandi bigomba gukomera cyangwa gufatirwa.

2.5 Ibikoresho, ibikoresho nibikoresho bigomba gushyirwaho neza. Igikoresho cyo kureremba kigomba kwagura icyerekezo-igice mubice byakazi mbere yo gutangira igikoresho cyimashini.

2.6 Iyo ukoresheje ikiruhuko cyo hagati cyangwa igikoresho cyo kuruhuka, ikigo kigomba guhinduka neza, kandi hagomba kubaho amavuta meza hamwe no gushyigikira imikoranire.

2.7 Iyo utunganya ibikoresho birebire, igice kigaragara inyuma yigitereko nyamukuru ntigomba kuba kirekire.

2.8 Iyo ugaburira icyuma, icyuma kigomba kwegera akazi gahoro gahoro kugirango wirinde kugongana; umuvuduko wikinyabiziga ugomba kuba umwe. Mugihe uhinduye igikoresho, igikoresho nigikorwa bigomba kubikwa intera ikwiye.

2.9 Igikoresho cyo gukata kigomba gukaza umurego, kandi uburebure bwagutse bwigikoresho cyo guhinduranya ntabwo burenze inshuro 2,5 zubugari bwigikoresho.

2.1.0 Mugihe utunganya ibice bya eccentricique, hagomba kubaho uburemere bukwiye bwo kuringaniza hagati yuburemere bwa chuck, kandi umuvuduko wikinyabiziga ugomba kuba ukwiye.

2.1.1. Hagomba kubaho ingamba zo gukingira igihangano cyakazi kirenze fuselage.

2.1.2 Guhindura igikoresho cyo gushiraho bigomba gutinda. Iyo igikoresho cyibikoresho kiri kuri mm 40-60 uvuye mugice cyo gutunganya igice cyakazi, intoki cyangwa ibiryo byakazi bigomba gukoreshwa aho, kandi ibiryo byihuse ntabwo byemewe kwishora mubikoresho.

2.1.3. Hano hari inzira nyamukuru hejuru, kandi birabujijwe gukoresha dosiye mugutunganya igihangano hamwe numwobo wa kare.

2.1.4. Birabujijwe gukoresha intoki zawe kugirango ufate umwenda utera kugirango usukure umwobo w'imbere.

2.1.5 Mugihe cyo kugaburira ibyuma byikora, icyuma gito gifata icyuma kigomba guhindurwa kugirango gihindurwe nigitereko kugirango wirinde gukoraho igikoma.

2.1.6 Mugihe ukata ibihangano binini kandi biremereye cyangwa ibikoresho, amafaranga ahagije yo gutunganya agomba kubikwa.

3. Igikorwa cyo guhagarara

3.1 Gabanya ingufu hanyuma ukureho urupapuro rwakazi.

3.2 Imikorere ya buri gice yakubiswe hasi kuri zeru, kandi ibikoresho birabarwa kandi bisukurwa.

3.3 Reba imiterere ya buri gikoresho cyo kurinda.

4. Kwirinda mugihe cyo gukora

4.1 Birabujijwe rwose ko abadakorera gukoresha imashini.

4.2 Birabujijwe rwose gukora ku gikoresho, igice kizunguruka cyigikoresho cyimashini cyangwa igihangano kizunguruka mugihe gikora.

4.3 Ntabwo byemewe gukoresha guhagarara byihutirwa. Mugihe byihutirwa, nyuma yo gukoresha iyi buto kugirango uhagarare, igomba kongera kugenzurwa ukurikije amabwiriza mbere yo gutangira igikoresho cyimashini.

4.4 Ntabwo byemewe gukandagira hejuru ya gari ya moshi, inkoni ya screw, inkoni isennye, nibindi bya lathe. Usibye amabwiriza, ntabwo byemewe gukoresha ikiganza ukoresheje ibirenge aho gukoresha amaboko.

4.5 Kubice bifite ibisebe, kugabanya imyobo cyangwa inzira nyamukuru kurukuta rwimbere, ibisakuzo bya mpandeshatu ntibyemewe guca umwobo wimbere.

4.6 Umuyaga ucanye cyangwa umuvuduko wamazi wa pneumatike yinyuma ya hydraulic chuck igomba kugera ku giciro cyagenwe mbere yuko ikoreshwa.

4.7 Iyo uhinduye ibihangano bito, mugihe uburebure burebure bwimbere bwimpande zombi zumutwe wigitanda burenze inshuro 4 diametre, ikigo kigomba gukoreshwa ukurikije amabwiriza yimikorere. Ikiruhuko cyo hagati cyangwa agatsinsino. Abashinzwe kurinda ibimenyetso nibimenyetso bagomba kongerwaho mugihe bagaragaye inyuma yumutwe wigitanda.

4.8 Mugihe ukata ibyuma byacitse cyangwa gukata byoroshye (harimo no gusya), hagomba kongerwamo ibyuma birinda, kandi ababikora bagomba kwambara ibirahure birinda.

ikindi

Hamwe no gukundwa kwaImashini ya CNC,ibikoresho byinshi kandi byikora bigenda bigaragara ku isoko.Imisarani gakondobafite ibyiza byabo bidasubirwaho kandi biracyari imashini zikenewe kubihingwa byinshi bitunganya.

1. Ibikoresho bya mashini bisanzwebirashoboka cyane

Igiciro cyo kuguraUmusarani wa CNCni inshuro nyinshi zihenze kuruta izisanzwe umusarani ufite imbaraga zimwe, hanyuma nyuma yo kubungabunga, gusana, gushyigikira ibikoreshwa nibindi biciro nabyo birarenze cyane.

2.Byinshi bikwiranye no gukora imashini ntoya

Mugihe uduce duto twibikorwa dukeneye kuba dukora,abakozi benshi bafite ubuhanga barashobora gukora imashini hamwe nibikoresho bisanzwe byimashini hamwe no gushushanya ibice.

3.Umushahara munini wa programmes za CNC nimpano nke

Porogaramu za CNC akenshi zisaba umushahara mwinshi, kandi hariho ubwoko bwinshi bwa sisitemu ya CNC. Biragaragara ko bigoye kubona umukoresha ubishoboyeIbikoresho bya mashini ya CNCkuruta umukozi wibikoresho bisanzwe.

4.Ku bijyanye nigiciro cyo kwinjiza ubucuruzi

Urebye igishoro cy’ibicuruzwa no gukoresha neza ibikoresho, ibigo byinshi bikomeza gukoraimashini isanzweibikoresho.

Muri rusange, nubwo inganda za CNC zabaye inzira nyamukuru mu iterambere ry’inganda zikora, ibikoresho byimashini zisanzwe ziracyafite inyungu zazo zidasanzwe mugihe cyo kumenyekanisha ibikoresho byubwenge. Hamwe no gukomeza kunoza ubwenge bwaIbikoresho bya mashini ya CNCmugihe kizaza, ibikoresho byimashini gakondo birashobora gusimburwa murwego runini, ariko ntibishoboka kubikuraho burundu.

| MODEL | CW61 (2) 63E | CW61 (2) 80E | CW61 (2) 100E | CW61 (2) 120E | CWA61100 |

| CAPACITIES | |||||

| Icyiza.kunyerera hejuru yigitanda | 630mm | 800mm | 1000mm | 1200mm | 1000mm |

| Byinshi.kunyerera hejuru yumurongo | 350mm | 485mm | 685mm | 800mm | 620mm |

| Uburebure | 750,1250.1750,2750,3750,4750,5750,7750,9750,11750mm | 1.5m 2m 3m 4m 5m 6m 8m 10m 10m 12m | |||

| Max.swing hejuru yicyyuho | 830mm | 1000mm | 1200mm | 1400mm | 780mm |

| Uburebure bwemewe | 230m | 8T | |||

| Ubugari bw'igitanda | 550mm | ||||

| UMUTWE | Φ130mm | ||||

| Umwobo | 105mm CYANGWA 130mm (BIKURIKIRA CW6180E +) | Ibipimo140 # | |||

| Kuzunguruka izuru | D-11 cyangwa C-11 | 3.15-315r / min cyangwa 2.5-250r / min | |||

| Kanda | 20120mm taper1: 20 (Φ140 , IHitamo RYA CW6180 +) | Imbere 21ubwoko,Guhindukira12ubwoko | |||

| Umuvuduko ukabije (Umubare) | 14-750RPM (INTAMBWE 18) | ||||

| GEAR BOX-INKINGI & FEEDS | 44ubwoko 1-120mm | ||||

| Urudodo rwibipimo (ubwoko) | 1-240mm (ubwoko 54) | 31ubwoko 1 / 4-24 T / I. | |||

| Inkingi zingana (Ubwoko) | 28-1 cm (ubwoko 36) | 45ubwoko 0.5-60mm | |||

| Urudodo rudasanzwe (ubwoko) | 0.5-60 DP (ubwoko 27) | 38ubwoko 1 / 2-56DP | |||

| Urudodo rwa diametral (ubwoko) | 30-1 tpi (ubwoko 27) | 56kinds 0.1-12mm | |||

| Kugaburira birebire (ubwoko) | 0.048-24.3mm / r (ubwoko 72) | 56ubwoko 0.05-6mm | |||

| Ingano yo kugaburira (ubwoko) | 0.024-12.15mm / r (ubwoko 72) | 3400mm / min, 1700mm / min | |||

| Ibiryo byihuse: Birebire./Cross | 4 / 2m / min | ||||

| Ingano yububiko: Diameter / Ikibaho | T48mm / 12mm CYANGWA T55mm / 12mm (kuri 5M +) | 48mm | |||

| CARRIAGE | 45 * 45mm | ||||

| Urugendo rwo kunyerera | 350mm | 420mm | 520mm | ||

| Urugendo rwo kuruhuka | 200mm | 650mm | |||

| Ingano yigikoresho shank | 32 * 32mm | 280mm | |||

| UMURONGO | |||||

| Diameter | 100mm | 120mm | Φ160mm | ||

| Kanda | MORSE # 6 | Ibipimo 80 # | |||

| Urugendo | 240mm | 300mm | |||

| MOTOR | |||||

| Moteri nyamukuru | 11kw | 22kw | |||

| Moteri ikonje | 0.09kw | 0.15kw | |||

| Moteri yo kugaburira byihuse | 1.1kw | 1.5kw | |||

Igihe cyo kohereza: Apr-14-2022