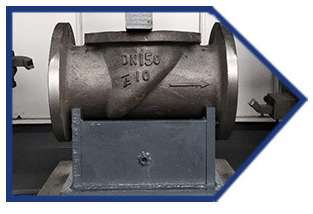

UwitekaImashini idasanzweikoreshwa cyane mugutunganya Valve (Ikinyugunyugu / Ikinyugunyugu / Irembo rya Ball / Umubumbe wa globe, nibindi ..), umubiri wa pompe, ibice byimodoka, ibice byubwubatsi nibindi.

Ikora kubintu byinshi bitandukanye byo gutunganya, nka: Isura yanyuma, uruziga rwo hanze, uruhande rwimbere, umwobo wimbere, gutobora, umugozi wumugozi, Bore-umwobo na Sphere. Irashobora kumenya automatike, yuzuye neza, itandukanye kandi itanga umusaruro mwinshi.Bikoreshwa cyane mubikorwa bya valve.

Ibyerekeyeinganda

Indangagaciro nibikoresho byifashishwa mugukingura no gufunga imiyoboro, kugenzura imigendekere, kugenzura no kugenzura ibipimo (ubushyuhe, umuvuduko, nigitemba) byikwirakwizwa. Ukurikije imikorere yacyo, irashobora kugabanywamo ibice bifunga,Kugenzura, kugenzura valve, nibindi.

Umuyoboro ni ikintu kigenzura sisitemu yo gutanga amazi. Ifite imirimo yo guca, kugenzura, gutandukana, gukumira imigendekere yinyuma, gutuza, gutandukana cyangwa kurengerwa, no kugabanya umuvuduko. Indangantego zikoreshwa muri sisitemu yo kugenzura amazi, uhereye kumurongo woroshye wo gufunga kugeza kumibiri itandukanye ikoreshwa muri sisitemu yo kugenzura byikora cyane, ifite ubwoko butandukanye kandi bwihariye.

Indangagaciro zikoreshwa cyane mubice bitandukanye. Ahanini peteroli, metallurgie, ingufu z'amashanyarazi, kubungabunga amazi, kubaka imijyi, kurwanya umuriro, imashini, amakara, ibiryo, nibindi.

Kuboneka

Ni izihe nyungu zaImashini idasanzwemu nganda za valve

RGucukura bifata ubwoko bwinshi-axis, kandi imikorere ikanozwa inshuro nyinshi.

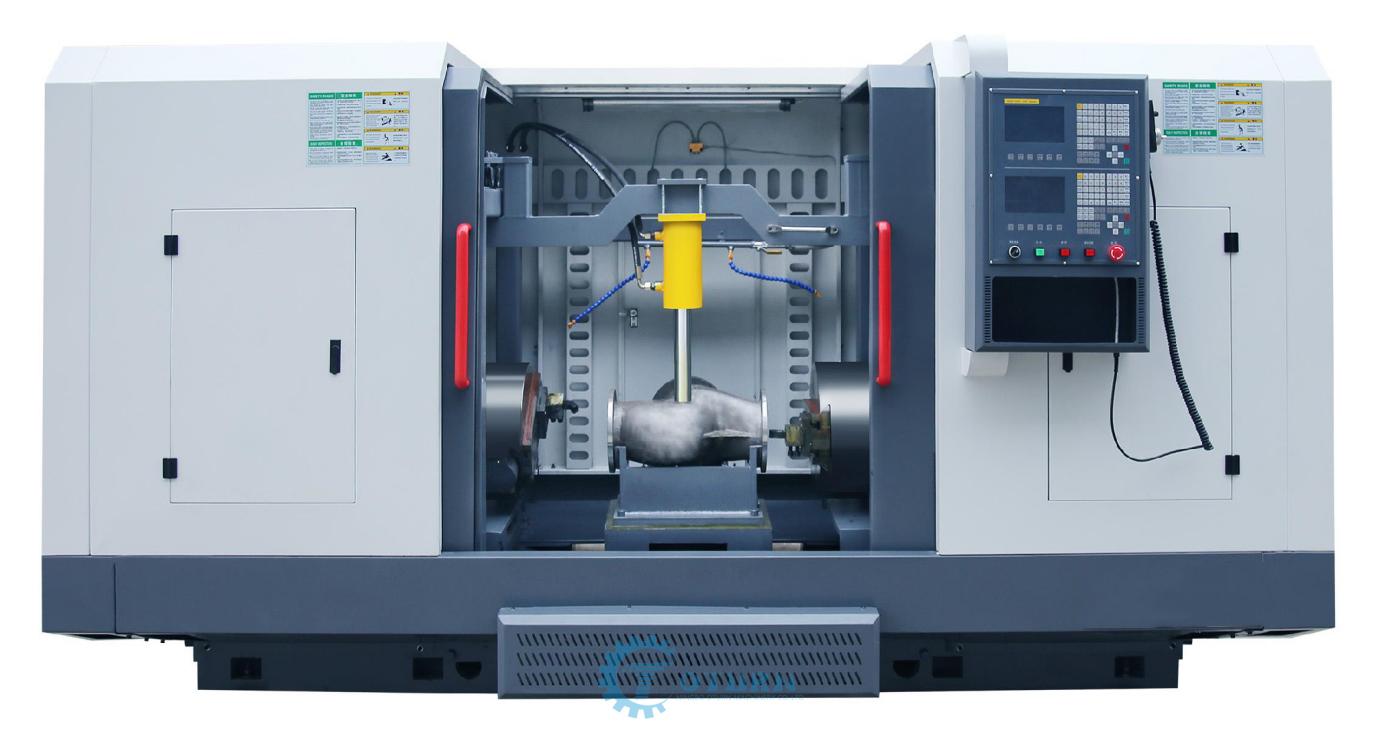

Kugera ku mitwe ibiri cyangwa itatu itunganyirizwa icyarimwe mugihe cyo gutunganya kugirango umenye ubuziranenge nibikorwa byiza byagutunganya imiyoboro ya pompe.

Sisitemu yihariye yemewe yo kugenzura imibare, ibikorwa byikora byuzuye.

Twasabye Imashini idasanzwe ya Valve

AbadusabyededImashini idasanzwe

1.Umubiri

Imashini ya Machine ikozwe muri rusange yujuje ubuziranenge bwimyenda yicyuma, gutunganya imashini, kurangiza, hamwe nuburyo butatu bwo kuvura gusaza kugirango bikureho burundu imihangayiko isigaye. Ubuso bwa gari ya moshi

Ikoresha uburyo bwo kuzimya amajwi arenze amajwi kandi bigatunganywa neza na gari ya moshi iyobora neza kugira ngo igikoresho gikorwe neza. √

2.Imashini idasanzwe ya Valve

Agasanduku k'umutwe

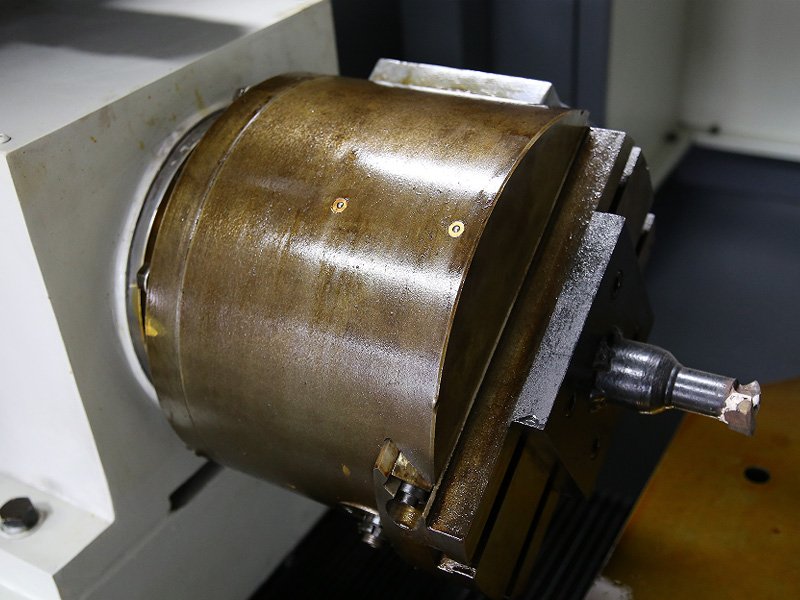

Agasanduku k'Umutwe gakozwe mu bikoresho byo mu rwego rwo hejuru, kandi uruziga nyamukuru rukozwe muri 20GrMnTAi, rwahimbwe, ruzimya, kandi rufite ubushyuhe, karubasi kandi ruzimya, kandi rwongewemo na gride ya silindrike yo mu nda no hanze.

Ikirangantego gifata ibyemezo-bihanitse-by-imirongo ibiri ya silindrike ya roller kugirango yizere neza kandi neza neza. Igiti nyamukuru gifata ibyiciro bitatu byihuta hamwe na moteri ifite ingufu nyinshi kugirango igere ku muvuduko muke

Umuyoboro munini, urashobora kwihanganira umutwaro uremereye, kunoza imikorere. √

7. Igikoresho cyo gusiga amavuta

Sisitemu yo gusiga ibikoresho ifite ibikoresho bya Nanjing Beqier bigenda bitera imbere, bigahora bisohora amavuta yo gusiga ahantu ho gusiga buri gice cyimuka, bikuraho imikorere yintoki.

Kunoza ubuzima bwa serivisi yigikoresho cyimashini. √

Imashini imitwe ibiri CNC

Ikinyugunyuguimashini idasanzwe

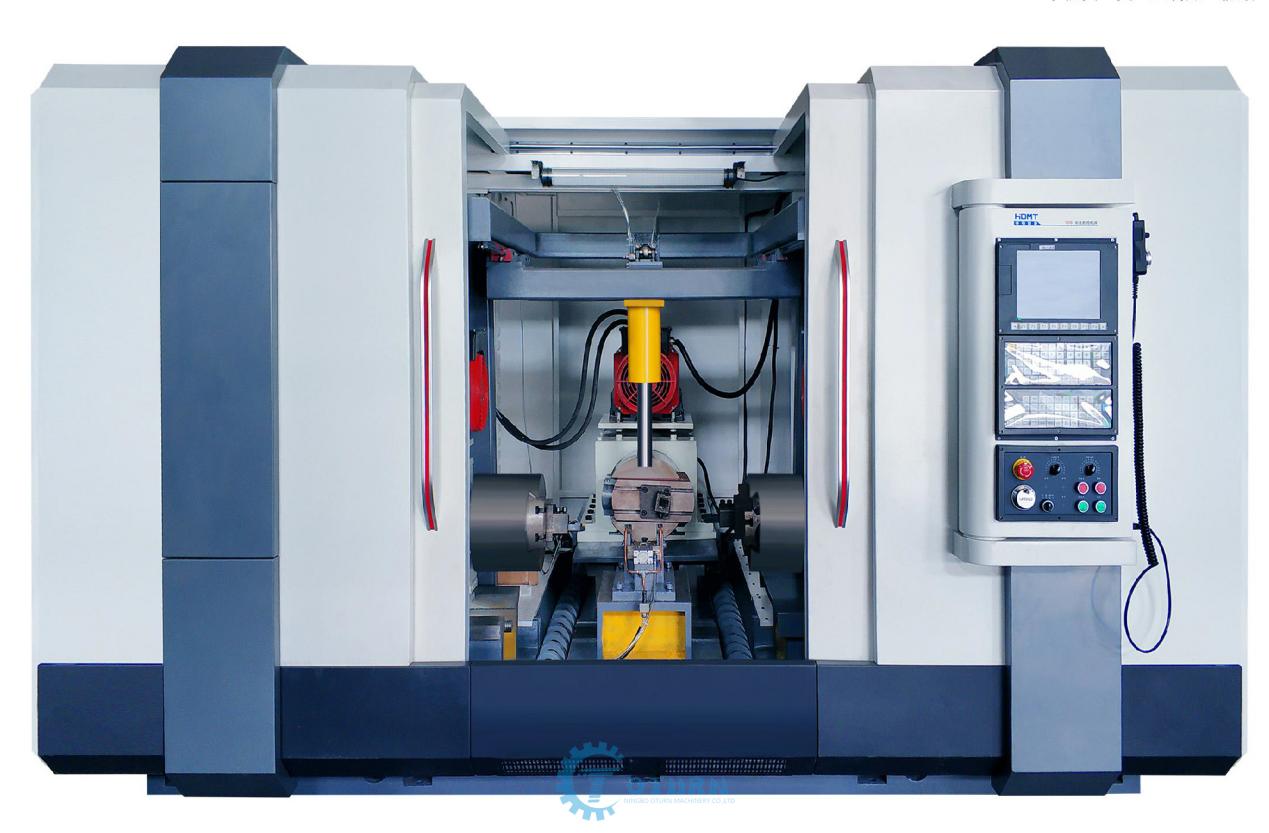

HDCX800 ihinduranya-gusya ikomatanya imashini,ikinyugunyuguibikoresho bidasanzwe byo gutunganya imashini bikoreshwa cyane cyane muri kinyugunyugu na zeru

Mugutunganya ibice, imashini zubwubatsi nibindi bice, isura yanyuma, umuzenguruko winyuma, spigot, umwobo wimbere, groove, umugozi, umwobo wa taper hamwe nuburyo bugaragara bwibikorwa bishobora gutunganywa.

Guhindukira. Inzira yo gutunganya igenzurwa na sisitemu ya GSK CNC, ishobora kumenya automatike, yuzuye neza, itandukanye, hamwe nibikorwa byinshi.

Ikintu nyamukuru

1. Imashini idasanzwe ya HDCX800 igenzurwa na sisitemu ya GSK CNC, ishobora kugerwaho no guhuza ibice bibiri.

Gutunganya ibyobo bya taper, insanganyamatsiko, hamwe nuburyo butandukanye. Sisitemu yayo ya CNC irahuye, ikomeye, kandi yoroshye gukora.

2. Umuhanda wa gari ya moshi uyobora ibiryo bikozwe mu cyuma cyiza cyo mu rwego rwo hejuru, cyakorewe uburyo butatu bwo gusaza nyuma yo gukara no kurangiza kugira ngo bikureho burundu imihangayiko yo mu mutima.

Ubuso bwakiriye super-amajwi yumuriro wo kuzimya kandi gukomera bigera kuri HRC55. Ubusobanuro, ubukana, hamwe nigikoresho cyibikoresho byimashini byemezwa no gusya gari ya moshi.

3.Ibice byoherejwe bitwarwa nu mupira wuzuye wumupira kandi ingamba za interpolation zikoreshwa mugukuraho icyuho, kwemeza kohereza no gutunganya ibikoresho byimashini.

4. Imbaraga zamashanyarazi zikoresha ibyiciro bitatu byoherejwe nintoki hamwe na moteri ifite ingufu nyinshi kugirango igere ku muvuduko muke na torque nyinshi, irashobora kwihanganira imitwaro iremereye, kandi igateza imbere imikorere.

5.Ibikoresho bifata hydraulic automatic clamping kugirango tunoze imikorere kandi bigabanye imbaraga zumurimo.

6. HDCX800 Imashini idasanzwe ya Valve,imashini yikinyugunyugu imashini idasanzweigikoresho gifata amavuta yibanze kugirango buri gice cyimuka gisizwe neza kandi gitezimbere ibikoresho byimashini.

Imashini idasanzwe Imiterere

Umutwe w'imbaraga

Imbaraga z'umutwe wa bokisi zikozwe mu bikoresho byo mu rwego rwo hejuru, kandi urufunguzo nyamukuru rukozwe mu bikoresho bya 20GrMnTAi, bitunganyirizwa mu guhimba, kuzimya, no gushyuha, gutwika, no kuzimya, hamwe no gusya cyane imbere no hanze.

Ikirangantego gifata NN30 yuruhererekane rwinshi-rwuzuye-imirongo ibiri ya silindrike ya roller kugirango yizere neza kandi neza neza.

Akazi

Imbonerahamwe ni umurimo wihariye udasanzwe wakozwe ukurikije ibice byatunganijwe. Ibirindiro byahagaritswe hamwe nudupapuro twahagaritswe byose bizimye kugirango tumenye neza aho akazi gakorerwa.

Gukata kumurimo bifata intoki kugirango zongere imikorere kandi zigabanye imbaraga zumurimo. Kandi imbonerahamwe irashobora kuzunguruka dogere 180, gukanda inshuro imwe, inshuro imwe Uzuza inzira zose.

Igikoresho cyikora cyo guhindura ibikoresho ikinyamakuru

Byuzuye byikora CNC igikoresho cyo guhindura ibikoresho, gishobora gufata ibikoresho 16, ibikoresho 20, ibikoresho 24, nibindi, bigahita bigenzurwa na sisitemu, hamwe nihuta ryibikoresho byihuta kandi byukuri.

- Umutwe w'imbaraga

Umutwe wimbaraga ukoresha moteri yihariye ya moteri + screw, ifite ibiranga ibintu bisobanutse neza, gukomera cyane, no kuramba.

- Igikoresho

-

Igikoresho nigikoresho kidasanzwe cyateguwe ukurikije ibice bigomba gutunganywa. Ibirindiro byahagaritswe hamwe nudupapuro twahagaritswe byose bizimye kugirango tumenye neza aho akazi gakorerwa. Igicapo cyafashwe na hydraulic clamping, itezimbere gutunganya neza kandi igabanya ubukana bwabakozi.

- Inama y'amashanyarazi

Inama y’amashanyarazi ifata ubwoko bwigenga bufunze, hamwe na sisitemu yo kugenzura, guhinduranya imirongo hamwe n’ikibuga cy’indege igenzura ibikoresho by’amashanyarazi, kandi ifite ibikoresho bikonjesha ikirere kugira ngo ibice by’amashanyarazi bigizwe n’imashini bikora bisanzwe kandi bitinjira mu mukungugu.

- CNC C.Sisitemu ya ontrol

Ifite imikorere yubuhanga bugenzura imiyoboro myinshi, gutunganya eshanu-axis, kwihuta cyane kandi-bisobanutse neza, guhinduranya no gusya, kugenzura guhuza hamwe nubundi bugenzuzi bwo hejuru bwa CNC.

Guhitamo ibikoresho:

Igenzura rya CNC

kugenzura ubukonje

Chip convoyeur

Kimwe cya kabiri cyo kurinda / kurinda byuzuye

Kubwoko butandukanye bwa valve, inzira zitandukanye ziratunganywa. Kurugero, ibikorwa byumusaruro nubwiteganyirize butandukanye bwa tekiniki bigomba gukorwa mbere yo gutunganywa. Ba injeniyeri bakeneye gukora imyiteguro ijyanye nigishushanyo mbonera cyibicuruzwa ubwabyo hamwe nibikoresho bidasanzwe byo gukora indege ya Huadian valve. Ibice byubusa bya valve birashobora gushushanywa no guta umucanga, gutera neza cyangwa guta ibishashara mugihe cyo gukora. Kuburyo bwo guhimba cyangwa gusudira, birakenewe gushushanya ukurikije ibihe byubusa.

Uwitekauburyo bwo gutunganya valvebiragoye, kandi agaciro kiyongereye kubicuruzwa ni bike. Ibyiza byo gukoresha rusange-intego cyangwaIbikoresho bya mashini ya CNCntishobora kugaragara. Gutunganya byuzuye bya valve bisaba no guhuza imashini nyinshi kugirango ugere kubikorwa byo gutunganya. Igihe cyose uhinduye ingano cyangwa ubwoko butandukanye, ugomba guhindura igikoresho cyimashini, hanyuma ugahindura inzira yarangiye kuva mubikorwa byabanjirije igikoresho cyimashini ihuye mugikorwa gikurikira. Ibi ntabwo byongera ikiguzi cyo gukora gusa, ahubwo binatakaza igihe kinini. Mubisanzwe, ibihangano bisaba ibisobanuro bihanitse cyane, kubera impinduka nyinshi zifatika, byongera amakosa yibikorwa byakazi. Inyungu zaindegebirigaragaza.

Kurugero, Kuriamarembo, guhinduranya impande eshatu zirashobora gukorwa kumashini imwe. Kugeza ubu, imashini idasanzwe ya HDMT irashobora icyarimwe gutunganya impande ebyiri cyangwa eshatu za flange flange icyarimwe, ikaba yoroshye kandi ikora neza, mugihe umusaruro gakondo Gusa flange imwe ya valve irashobora gutunganyirizwa icyarimwe, bitwara igihe kandi bisaba akazi. Muri ubwo buryo, gucukura flange kumpande eshatu cyangwa ebyiri za valve nazo zishingiye kumahame amwe, ntabwo azamura imikorere gusa, ahubwo anagabanya kwihanganira imyanya yumwobo.

Igikorwa cyaimashini idasanzwenabwo biroroshye cyane, moderi zose zabonye igishushanyo cyikora, gusa zikeneye kwinjiza ibipimo. Ibi bigabanya cyane ibikorwa byintoki, bigabanya amafaranga yumurimo, kandi bigatwara igihe nimbaraga. Niba hari ibintu birenze urugero cyangwa ikindi kibazo kibaye mugihe cyo gukora, imashini izahita itanga impuruza cyangwa ihita ifunga, kugirango wirinde kwangirika kwimashini kurwego runini.

Indege ya valve imaze kurangira, uyikoresha agomba kuzimya amashanyarazi ajyanye nayo, gukora akazi keza ko gukora isuku, kandi agakoresha amavuta yumwuga kugirango asane kandi abungabunge indege ya valve. Hariho ibintu byinshi bigomba kwitabwaho mugihe cyo gukora imashini idasanzwe ya valve. Imashini idasanzwe ya valve ntishobora gukora imirimo nko guhindura ibikoresho, kugenzura no gukuraho mugihe gikora. Mugihe cyose cyimikorere yimashini yihariye ya valve, abakozi nabakozi bireba ntibagomba kuva mukazi kabo, kandi bagomba gukora akazi keza ko kugenzura. Ibikoresho nkibikoresho, ibikoresho, nicyuma bigomba gufatanwa neza, bitabaye ibyo ibibazo bimwe na bimwe bigenda byakazi. Imikorere mibi irashobora gutera ibikomere bitari ngombwa. Niba icyuma kimenetse cyangwa cyacitse, bigomba gusimburwa mugihe. Mubikorwa byimikorere isanzwe, ntidushobora gukora ku buryo butaziguye hejuru yumurimo wamaboko yacu, ntidushobora no gukuraho ibintu biteye akaga nko gukata amaboko. Ibi ntibizababaza amaboko yacu gusa, ahubwo bizanatera ibyuma biguruka. Impanuka mumaso. Mugihe cyakazi cyaindege idasanzwe, ugomba kwambara hejuru ijyanye, kwambara agapira k'akazi, kandi urebe neza ko wuzuza umusatsi wawe mumutwe. Mugihe cyo gupakurura no gupakurura ibihangano binini, gerageza gukoresha ibikoresho byo guterura, kugirango ibikorwa byose bibane neza mubuhanga, kandi imikorere yumutekano izaba myinshi.

Igihe cyo kohereza: Nzeri-22-2021