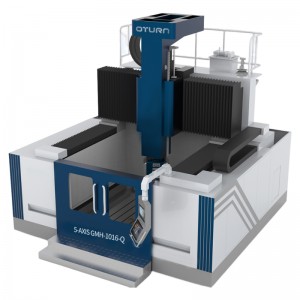

Ikigo cyerekana imashini ya CNC

Ikigo cyerekana imashini ya CNC

Imashini yo gucukura CNC

Ibiranga imashini

Bosm DCImashini zo gucukura no gusya CNCByakoreshejwe cyane mugusya neza no gusya ibihangano hamwe numurongo wubugari bwibintu muburyo bugaragara. Binyuze mu mwobo no mu mwobo uhumye birashobora gucukurwa kubice bimwe nibikoresho hamwe. Gutunganya imashini hamwe na CNC mugenzuzi, imikorere iroroshye cyane. Irashobora gutahura automatike, ibisobanuro bihanitse, byinshi bitandukanye nibikorwa byinshi.

Kugirango twuzuze ibisabwa byo gutunganya abakoresha batandukanye, Isosiyete yacu yateje imbere ibicuruzwa bitandukanye byarangiye.Bishobora kandi gutegurwa no gutegurwa ukurikije ibyo abakoresha bakeneye.

Imiterere yimashini

Ibikoresho bigizwe ahanini nameza yigitanda, gantry igendanwa, indogobe igendanwa, gucukura no gusya umutwe wumutwe, ibikoresho byo gusiga amavuta hamwe nigikoresho cyo gukingira, ibikoresho bikonjesha bikwirakwiza, sisitemu yo kugenzura ibyuma bya sisitemu, sisitemu ya hydraulic, sisitemu yamashanyarazi, nibindi. Igikoresho cyimashini gifite imyanya ihanitse ubunyangamugayo no gusubiramo umwanya.

1. Uburiri & akazi:

Igitanda cyimashini gisudira ibice byubaka ibyuma, kandi ikadiri nyamukuru itunganywa nibice byubatswe. Nyuma yo guhangayika kwimbere gukuweho no kuvura ubushyuhe bwubusaza, bifite imbaraga nziza kandi zihamye kandi nta guhinduka. Imbonerahamwe ikora ikozwe mu guta ibyuma HT250. Imbonerahamwe irashobora gukoreshwa kurigufatira hamwe. Irashobora kandi kuba ifite pneumatic fixture, ikaba yoroshye kandi yihuse mugukata ibihangano byakazi,. Ubushobozi ntarengwa bwo gutwara bwakazi ni toni 1. Uruhande rwo hejuru rw'ibumoso rw'igitanda rushyizwe mu buryo buhagaritse hamwe na ultra-high-power ubushobozi bwo kuzunguruka umurongo uyobora umurongo hamwe na rack precision. Moteri ya gantry itwarwa na sisitemu ya AC servo na sisitemu ya rack mu cyerekezo X. Ibishobora guhindurwa bikwirakwizwa hejuru yigitanda, gishobora guhindura byoroshye urwego rwameza yigitanda.

2. Kwimura kantileveri:

Gantry yimukanwa yimyenda ifite ibyuma byubatswe bitunganywa nyuma yo gukuraho imihangayiko yimbere mugukoresha ubushyuhe bwubusaza, hamwe ningufu nziza kandi zihamye kandi nta guhinduka. Babiri bazunguruka umurongo uyobora hamwe nubushobozi buhebuje bwo kwishyiriraho bishyirwa imbere no hejuru ya gantry. Imirongo izunguruka ifite ubushobozi bwo gutwara ibintu birenze urugero, umurongo wumupira wuzuye hamwe na moteri ya servo byashyizwe hejuru kugirango icyapa cyerekana amashanyarazi umutwe ugenda mu cyerekezo cya Y-axis. Umutwe wimbaraga zo gucukura washyizwe kumurongo wamashanyarazi. Kugenda kwa gantry kugerwaho no kuzunguruka umupira wumupira utwarwa na moteri ya servo unyuze hamwe.

3. Kwimura indogobe:

Kwimuka kunyerera kwimuka ni umunyamuryango wibyuma. Inzira ebyiri zizunguruka ziyobora hamwe nubushobozi buhebuje bwo gutwara ibintu, urutonde rwumupira wuzuye hamwe na moteri ya servo byashyizwe kumurongo wo kunyerera kugirango utware umutwe wimbaraga zo kwimuka kugirango werekeza mu cyerekezo cya z-axis, ushobora kumenya byihuse imbere, kora imbere, byihuse gusubira inyuma no guhagarika umutwe wimbaraga. Ifite imirimo yo kumena chip yikora, gukuramo chip no guhagarara.

4. Umutwe w'ingufu:

Moteri idasanzwe ya servo spindle ikoreshwa mugucukura ingufu z'umutwe. Umwihariko wa spindle itwarwa nu menyo ya synchronous amenyo kugirango umenye impinduka zumuvuduko udahinduka. Ibiryo bitwarwa na moteri ya servo na ball ball.

Y-axis irashobora guhuzwa no kugenzurwa na kimwe cya kabiri gifunze, gishobora kumenya umurongo no kuzenguruka interpolation. Impera nyamukuru ya shaft ni er taper umwobo wogosha umwitozo cyangwa gusya, hamwe nibisobanuro bihanitse, gukata umuvuduko mwinshi, imikorere yo guhindura ibikoresho bya pneumatike, guhitamo hamwe nibinyamakuru byubwoko bwikinyamakuru, ibikoresho byikinyamakuru ubushobozi bwumunani, guhindura ibikoresho biroroshye, murwego rwo hejuru rwo kwikora yo gutunganya intoki.

5. Igikoresho cyo gusiga cyikora nigikoresho cyo gukingira:

Imashini ifite ibikoresho byo gusiga byikora, bishobora guhita bisiga amavuta abiri nka gari ya moshi iyobora, imiyoboro ya screw na rack. X.

6. Sisitemu yo kugenzura KND:

6.1. Hamwe nimikorere ya chip yameneka, chip yameneka hamwe na chip yameneka irashobora gushirwa kumurongo wimashini.

6.2. Hamwe naigikoresho cyo guterura ibikoresho, igikoresho cyo guterura uburebure gishobora gushirwa kumurongo wimashini. Iyo gucukura kugeza kuri ubu burebure, biti ya myitozo irazamurwa vuba hejuru yakazi, hanyuma chip irajugunywa, hanyuma yihuta yerekeza hejuru yubucukuzi hanyuma ihita ihinduka akazi mbere.

6.3. Igikorwa gikomatanyije cyo kugenzura agasanduku hamwe nintoki zifite ibikoresho bya sisitemu ya CNC, USB ya USB na ecran ya LCD. Kugirango byorohereze porogaramu, kubika, kwerekana no gutumanaho, interineti ikora ifite imirimo yo kuganira na man-mashini, indishyi z'amakosa hamwe no gutabaza byikora.

6.4. Ibikoresho bifite imikorere yo kureba no kugenzura aho umwobo mbere yo gutunganya, bityo imikorere iroroshye cyane.

Ibisobanuro

| Icyitegererezo | BOSM-DC60050 | |

| Icyiza. Ingano y'akazi | Uburebure × ubugari (mm) | 2600 × 500 |

| Vertical Ram gucukura ingufu umutwe | Umubare (igice) | 1 |

| Umuyoboro wa taper | BT40 | |

| Gucukura diameter (mm) | Φ2-Φ26 | |

| Umuvuduko ukabije (R / min) | 30 ~ 3000 | |

| Imbaraga zizunguruka (kw) | 15 | |

| Intera iri hagati yizuru rya spindle nameza yakazi (mm) | 150-650mm | |

| X-axis (ingendo zinyuranye) | Indwara ntarengwa (mm) | 500 |

| X-axis igenda yihuta (M / min) | 0 ~ 9 | |

| X-axis servo moteri (kw) | 2.4 * 1 | |

| Y-axis (ingendo ndende) | Indwara ntarengwa (mm) | 2600 |

| Y-axis yihuta (M / min) | 0 ~ 9 | |

| Imbaraga za y-axis servo moteri (kw) | 2.4 * 1 | |

| Z axis (Vertical ram feed feed movement) | Indwara ntarengwa (mm) | 500 |

| Kwimuka umuvuduko wa Z axis (M / min) | 0 ~ 8 | |

| Z-axis servo moteri (kw) | 1 × 2.4 hamwe na feri | |

| Igipimo cyimashini | Uburebure × ubugari × uburebure (mm) | 5400 × 2180 × 2800 |

| Umwanya uhagaze | X / Y / Z. | ± 0.05 / 300mm |

| Gusubiramo neza | X / Y / Z. | ± 0.025 / 300mm |

| Uburemere bukabije (t) | 4.5 | |

Kugenzura Ubuziranenge

Buri mashini ihindurwamo lazeri interferometero yo mu Bwongereza RENISHAW yo mu Bwongereza, igenzura neza kandi ikanishyura amakosa y’ikibuga, gusubira inyuma, aho ihagaze neza, hamwe n’imyanya ihagaze neza kugira ngo imashini ikore neza, ihagaze neza, kandi itunganyirizwe neza. . Ikizamini cy'umupira Buri mashini ikoresha igeragezwa ry'umupira woherejwe n’isosiyete yo mu Bwongereza RENISHAW kugira ngo ikosore neza uruziga nyarwo hamwe n’imashini ya geometrike, kandi ikore ubushakashatsi bwo gukata uruziga icyarimwe kugira ngo imashini ya 3D ikoreshwe neza kandi izenguruke.

Imashini ikoresha ibikoresho

1.1 Ibikoresho bisabwa ibidukikije

Kugumana urwego ruhoraho rwubushyuhe bwibidukikije ni ikintu cyingenzi cyo gutunganya neza.

(1) Ubushyuhe bwibidukikije buboneka ni -10 ℃ ~ 35 ℃. Iyo ubushyuhe bwibidukikije ari 20 ℃, ubuhehere bugomba kuba 40 ~ 75%.

.

Ntigomba kurenza ± 2 ℃ / 24h.

1.2 Amashanyarazi yumuriro: icyiciro 3, 380V, ihindagurika rya voltage muri ± 10%, inshuro zitanga amashanyarazi: 50HZ.

1.3 Niba voltage mukarere gakoreshwa idahindagurika, igikoresho cyimashini kigomba kuba gifite amashanyarazi yagenwe kugirango harebwe imikorere isanzwe yimashini.

1.4. Igikoresho cyimashini kigomba kuba gifite ishingiro ryizewe: insinga yubutaka ni insinga z'umuringa, diameter ya wire ntigomba kuba munsi ya 10mm², kandi kurwanya ubutaka ntibiri munsi ya 4 oms.

1.5 Kugirango hamenyekane imikorere isanzwe yibikoresho, niba umwuka uhumanye uturuka mu kirere utujuje ibyangombwa bisabwa n’ikirere, hagomba kongerwaho ibikoresho byogeza ikirere (dehumidification, degreasing, filter) imashini ifata umwuka.

1.6. Ibikoresho bigomba kubikwa kure yizuba ryizuba, kunyeganyega nubushyuhe, no kuba kure yumuriro mwinshi, imashini zo gusudira amashanyarazi, nibindi, kugirango birinde gutsindwa kwimashini cyangwa gutakaza neza kwimashini.

Mbere & Nyuma ya Serivisi

1) Mbere yumurimo

Binyuze mu kwiga icyifuzo namakuru akenewe kubakiriya noneho ibitekerezo kuri injeniyeri zacu, itsinda rya tekinike rya Bossman rishinzwe itumanaho rya tekinike hamwe nabakiriya no gutegura ibisubizo, rifasha abakiriya guhitamo igisubizo kiboneye cyimashini hamwe nimashini zibereye.

2) Nyuma yumurimo

A.Imashini ifite garanti yumwaka umwe kandi yishyuwe kubungabunga ubuzima.

B.Mu gihe cya garanti yumwaka umwe nyuma yimashini igeze ku cyambu, BOSSMAN izatanga serivisi zokubungabunga kandi ku gihe ku makosa atandukanye atakozwe n'abantu ku mashini, kandi asimbure ku gihe cyose ubwoko bw’ibice byangiritse bitakozwe n'abantu ku buntu ishinzwe. Kunanirwa mugihe cya garanti bigomba gusanwa kubiciro bikwiye.

C. Inkunga ya tekiniki mumasaha 24 kumurongo, TM, Skype, E-imeri, gukemura ibibazo bijyanye mugihe. niba bidashobora gukemurwa, BOSSMAN izahita itegura ko injeniyeri nyuma yo kugurisha igera aho ikosorwa, umuguzi akeneye kwishyura VISA, amatike yindege nicumbi.

Urubuga rwabakiriya