Imashini Iremereye CNC Imashini yo gusya

Imashini yo gucukura no gusya CNC

Imashini yihuta ya CNC imashini yo gusya no gusya

Gukoresha Imashini

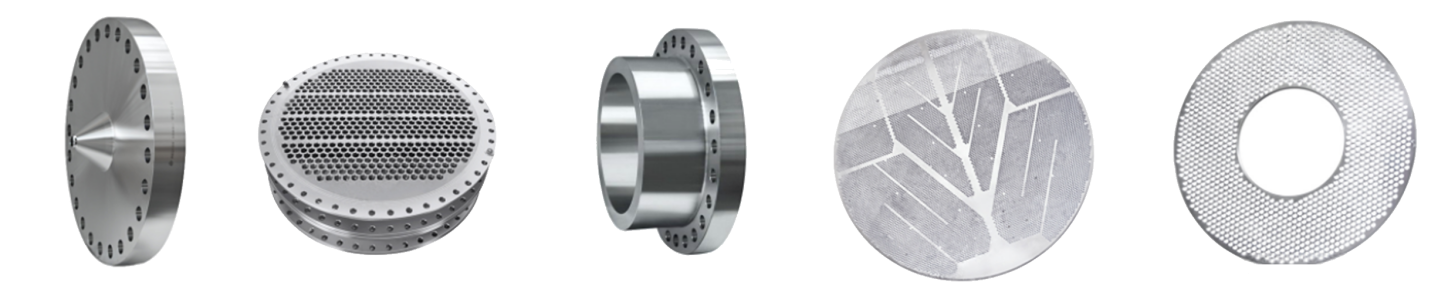

Imashini zo gucukura no gusya za CNC zikoreshwa cyane cyane mugucukura neza ibihangano hamwe nubunini murwego rwiza nka plaque, flanges, disiki nimpeta. Binyuze mu mwobo no mu mwobo uhumye birashobora gucukurwa kubintu bitandukanye. Imashini igenzurwa muburyo bwa digitale hamwe nibikorwa byoroshye. Irashobora kugera kuri automatike, yuzuye neza, ubwoko bwinshi, umusaruro mwinshi.

Kugirango duhuze ibyifuzo byabakoresha batandukanye, isosiyete yacu yakoze imashini zitandukanye. Usibye imiterere isanzwe, irashobora kandi gutegurwa ukurikije ibyo abakiriya bakeneye.

Imiterere yimashini

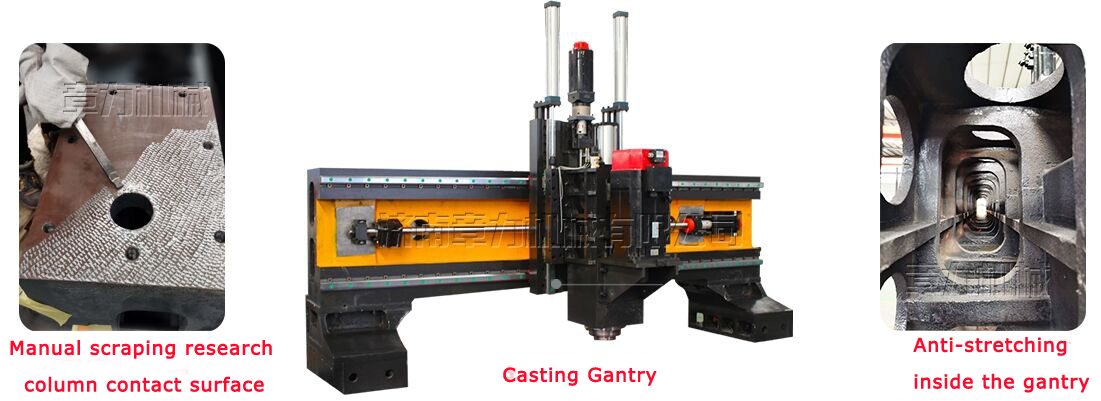

Ibi bikoresho bigizwe ahanini nameza yigitanda, kwimuka gantry, kugenda kuntambwe yo kunyerera, gucukura no gusya, ibikoresho byo gusiga amavuta hamwe nibikoresho birinda, ibikoresho bikonjesha, sisitemu yo kugenzura CNC, sisitemu yamashanyarazi nibindi. Gushyigikira no kuyobora umurongo uzunguruka nuyobora neza neza, imashini ifite imyanya ihanitse kandi ihagaze neza.

1)Akazi :

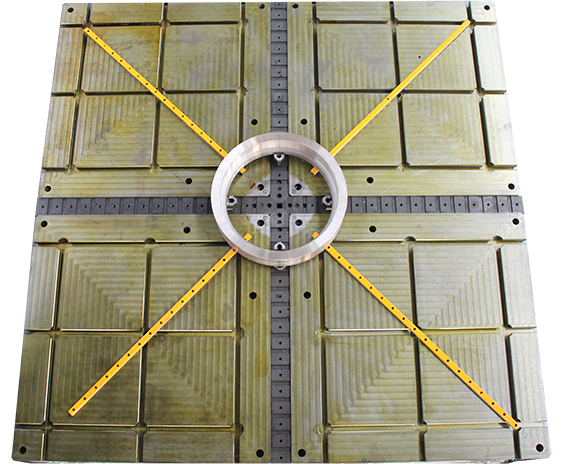

Imbonerahamwe ikora ifata imiterere ya casting, kandi indege ifite T-slot ifite imiterere yuzuye yo kurangiza kugirango ifate ibihangano. Hejuru yigitanda, T-ibibanza byateguwe. Sisitemu yo gutwara ikoresha moteri ya AC servo na ball ball isobanutse kugirango igendere kumpande zombi kugirango gantry yimuke mu cyerekezo Y-axis. Ibishobora guhindurwa bikwirakwizwa hepfo yigitanda, gishobora guhindura byoroshye urwego rwameza yigitanda.

2)Movinggantry :

Gantry igendanwa ikozwe hamwe nicyuma cyumuhondo 250, hamwe na super-high-power-power-roting umurongo uyobora ibice bibiri byashyizwe kuruhande rwimbere rwa gantry. Igice cyumupira wuzuye hamwe na moteri ya servo ituma imbaraga zumutwe zinyerera zerekeza muri X-axis. Umutwe w'ingufu zo gucukura washyizwe kumurongo wamashanyarazi. Kugenda kwa gantry bigaragazwa na moteri ya servo itwara umugozi wumupira kumupira wumupira unyuze neza.

3)Movingkunyerera :

Igikoresho cyo kunyerera kigendanwa nikintu kigizwe nicyuma cyubaka. Ibice bibiri bya ultr-high-power ya NC ya gari ya moshi hamwe nu murongo wuzuye wa ball ball screw hamwe na kugabanya umubumbe mwinshi cyane bihujwe na moteri ya servo kugirango itware umutwe wimbaraga. Kwimuka mu cyerekezo cya Z-axis birashobora kumenya byihuse imbere, gukora imbere, gusubiza inyuma, no guhagarika imbaraga zumutwe. Hamwe no kumena chip byikora, gukuramo chip, guhagarika imirimo.

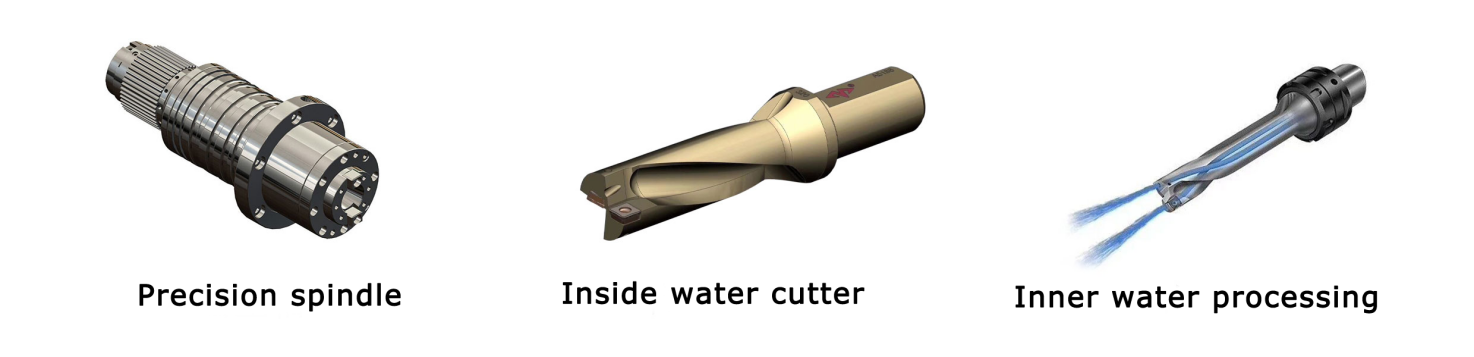

4)Umutwe w'ingufu(Spindle):

Umutwe wimbaraga zo gucukura ukoresha moteri yabugenewe ya servo spindle yabugenewe, itwara spindle yihariye yabugenewe mukwihutisha umukandara winyo wamenyo kugirango wongere umuriro. Spindle ikoresha imbere ya gatatu, ibiri, na gatanu-Imirongo Yabayapani ihuza impande zose kugirango igere ku muvuduko udahinduka. Gusimburwa byihuse kandi byoroshye, ibiryo bitwarwa na servo moteri na ball ball. X na Y ishoka irashobora guhuzwa, kandi igice-gifunze loop igenzurwa ikoreshwa kugirango igere kumurongo no kuzenguruka interpolation.

Impera ya Spindle ni BT40 umwobo wafashwe, ufite ibikoresho bya Rotorfoss byihuta byihuta biva mu Butaliyani, bishobora gukoresha imyitozo yihuta ya U (imyitozo yubukazi) hamwe na bito bito kugirango isohore amazi. menya gutunganya umwobo wimbitse kandi urinde igikoresho cyo kugabanya ikiguzi cyo gukoresha.

5) Igikoresho cyo gusiga cyikora nigikoresho cyo gukingira:

nka gari ya moshi iyobora, imiyoboro iyobora, ibisakuzo, nibindi, bidafite inguni zapfuye kugirango ubuzima bwa serivisi bwibikoresho byimashini. X-axis na Y-axis yigikoresho cyimashini zifite ibikoresho bitwikiriye umukungugu birinda umukungugu, kandi abashinzwe umutekano batagira amazi bashyirwaho hafi yakazi.

6)Sisitemu yo kugenzura CNC:

6.1 Hamwe nimikorere yo kumena chip, igihe cyo kumena chip hamwe na chip yameneka irashobora gushirwa kumurongo wimashini.

6.2 Hamwe nimikorere yo guterura ibikoresho, uburebure bwo guterura ibikoresho burashobora gushirwa kumurongo wimashini. Iyo gucukura kuri ubu burebure, biti ya drill irazamurwa vuba hejuru yakazi, hanyuma chip irajugunywa, hanyuma yihuta-yerekejwe hejuru yubucukuzi hanyuma ihita ihinduka akazi.

6.3Ibikorwa bikomatanyirijwe hamwe kugenzura agasanduku hamwe nintoki zifata intoki zifata sisitemu yo kugenzura imibare, kandi ifite USB interineti hamwe na LCD y'amazi ya kirisiti yerekana. Kugirango byorohereze porogaramu, kubika, kwerekana no gutumanaho, interineti ikora ifite imikorere nkibiganiro byabantu-imashini, indishyi zamakosa, hamwe no gutabaza byikora.

6.4Imashini ifite imikorere yo kureba no kugenzura aho umwobo mbere yo gutunganya, kandi imikorere iroroshye cyane.

7)Gari ya moshi

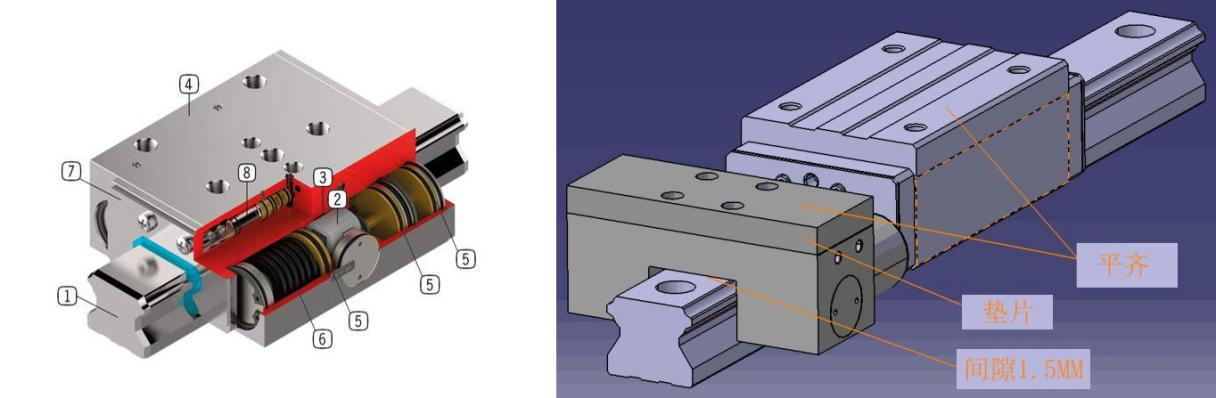

Clamp igizwe numubiri wa clamp hamwe na actuator. Nibikorwa-bihanitse byimikorere ikoreshwa hamwe no kuzunguruka umurongo uyobora. Itanga imbaraga zikomeye zo gufatisha binyuze mu ihame ryo kwaguka. Ibintu byongera ubukana.

Ibiranga:

- Umutekano kandi wizewe, imbaraga zikomeye zo gufatana, gufatira XY axis itagendagenda mugihe cyo gucukura no gutunganya.

- Imbaraga zo hejuru zifata cyane, ongera ubukana bwibiryo bya axial, kandi wirinde kugenda mikorobe iterwa no kunyeganyega.

- Igisubizo cyihuse, gufungura no gufunga igihe cyo gusubiza ni amasegonda 0.06 gusa, arinda igikoresho cyimashini kandi atezimbere ubuzima bwa screw.

- Kuramba, nikel isize hejuru, imikorere myiza yo kurwanya ingese.

Igishushanyo gishya kugirango wirinde ingaruka zikomeye mugihe ufashe.

8)Gukuramo chip byikora no gukwirakwiza ibikoresho bikonjesha:

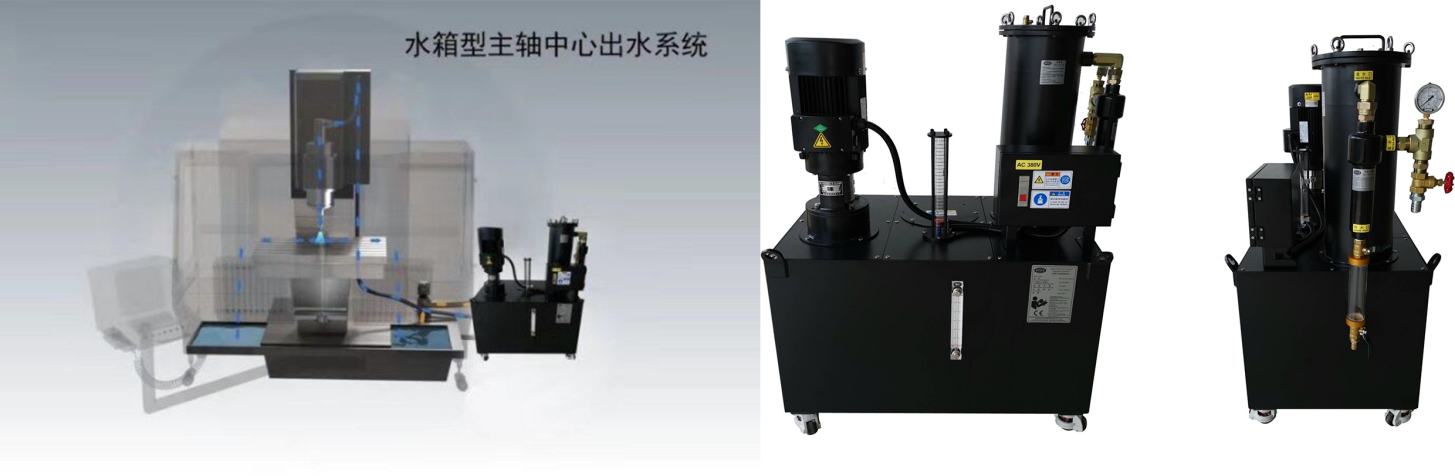

Gukuramo chip byikora byateguwe inyuma yumwanya wakazi hanyuma akayunguruzo karateguwe kumpera. Gukuramo chip byikora ni ubwoko bwurunigi, kandi pompe ikonjesha yashyizwe kuruhande rumwe. Isohoka rya chip ihujwe na sisitemu yo hagati yo kuyungurura amazi. Imashini ikonjesha yinjira muri chip. Chip ejector lift pompe itwara ibicurane muri sisitemu yo hagati yo kuyungurura amazi. Umuvuduko ukabije wo gukonjesha pompe ikwirakwiza ibishishwa byo gukata no gukonjesha. Kandi ifite ibikoresho byo gutwara trolley, byoroshye cyane gutwara ibyuma. Ibi bikoresho bifite sisitemu yo gukonjesha imbere ninyuma yo gukata. Iyo gucukura ku muvuduko mwinshi, ibishishwa bikonjeshwa namazi yimbere no hanze mugihe cyo gusya.

Impuruza y'amazi make

1) Iyo gukonjesha muyungurura biri kurwego rwo hagati rwamazi, sisitemu ihita ihuza moteri kugirango itangire, na coolant mugukuraho chip ihita yinjira mumashanyarazi. Iyo urwego rwo hejuru rwamazi rugeze, moteri ihita ihagarika akazi.

2) Iyo gukonjesha muyungurura biri kurwego rwo hasi, sisitemu izahita itera urwego rwamazi igipimo cyo gutabaza, spindle izahita ikuramo igikoresho, hanyuma imashini ihagarike akazi.

9)Sisitemu yo Gusohora Hagati System

Imashini ifite sisitemu yo hagati yo kuyungurura amazi nkibisanzwe, ishobora gushungura neza umwanda uri muri coolant. Sisitemu y'amazi yo gutera imbere irashobora kubuza ibyuma byuma kurigata mugikoresho mugihe cyo gutunganya, kugabanya kwambara, kongera ubuzima bwibikoresho, kunoza igishusho cyakazi, Kurangiza amazi yumuvuduko mwinshi wumuvuduko wicyuma urashobora kurinda neza ubuso bwakazi, kurinda umuvuduko mwinshi wihuta, kurinda umwanda guhagarika uruziga, no kuzamura ubwiza bwibikorwa byakazi no gukora neza.

10)Imipira yumupira hamwe nintebe ihuriweho:

Moteri ya moteri nigicuruzwa cyibanze cyane gihuza umupira na moteri. Inguni ihuza impande zombi (icyiciro cya C5 cyerekana neza) ihuriweho kugirango irusheho kunoza ukuri no kwemeza zeru zeru zeruye zumupira wumupira mugihe moteri iri imbere kandi igaruka. Irakwiriye cyane cyane kubikoresho byihuta.

Inteko isobanutse neza: imipira yumupira na moteri byashyizwe murimwe binyuze muri moteri. Mugabanye kwibeshya kwibikoresho bya moteri na shitingi ya ball ball, ubigenzure kuri plus cyangwa ukuyemo 0.01mm, kandi perpendicularitike yisura yanyuma ni 0.01.

11)Imeza-ine yimeza yibanda kumeza(Kubishaka)

Imbonerahamwe yimikorere yibikoresho-yonyine ifite ibikoresho bine-jaw hydraulic-yibanda kuri chuck. Urupapuro rwakazi rushobora guhurizwa mu buryo bwikora muri clamp imwe nta buri gihangano gikora irondo kugirango kibone ikigo. Gufata birihuta kandi byoroshye.

Gukemura ikibazo cyuko igice cyakazi gifite uruziga ruri munsi ya mm 1600 ya diametre gifatanwa no gukanda isahani nyuma yo kugaburira hanyuma ugashakisha ikigo, gitwara igihe gito kandi kigatwara igihe kinini cyo gufunga kuruta igihe cyo gutunganya.

Kwishyira ukizana kwa jaw-chuck chuck yigenga yigenga hamwe nigituba kinini cyumusaya bituma bigora akazi ko gukora ku rwasaya mugihe ufashe. Imiterere ya strip hamwe na padi irakoreshwa.Bikemura ikibazo cyuko urwasaya rwa hydraulic cyangwa pneumatike rufite ingendo nke ku isoko kandi ibihangano binini bizagira ingaruka ku rwasaya iyo bizamuye, bikangiza kwangirika.

Imisaya ine iri ku kazi kari mu buryo budashobora gusenyuka, kandi kuvanaho intebe yinyuma ni urubuga rusanzwe hamwe na T-groove yonyine.Byongera urwego rwo gusaba mubindi bikoresho usibye impeta.

Ibisobanuron

| Icyitegererezo | BOSM-DT1010 | BOSM-DT2010 | BOSM-DT2016 | BOSM-DT2525 | |

| Ingano y'akazi | Uburebure * Ubugari (mm) | 1000x1000 | 2000x1000 | 2000x1600 | 2500x2500 |

| Umutwe wo gucukura | Kanda | BT40 / BT50 | BT40 / BT50 | BT40 / BT50 | BT40 / BT50 |

| Gucukura diameter (mm) | Φ40 / Φ60 | Φ40 / Φ60 | Φ40 / Φ60 | Φ40 / Φ60 | |

| Kanda diameter (mm) | M24 / M36 | M24 / M36 | M24 / M36 | M24 / M36 | |

| Umuvuduko ukabije (r / min) | 30 ~ 3000 | 30 ~ 3000 | 30 ~ 3000 | 30 ~ 3000 | |

| Imbaraga (Kw) | 15/22 | 15/22 | 15/22 | 15/22 | |

| Intera kuva munsi yumutwe wa spindle kugeza kumurimo wakazi (mm) | 200 ~ 600/400 ~ 800 | 200 ~ 600/400 ~ 800 | 200 ~ 600/400 ~ 800 | 200 ~ 600/400 ~ 800 | |

| Ongera usubiremo imyanya uracy X / Y / Z) | X / Y / Z. | ± 0.01 / 1000mm | ± 0.01 / 1000mm | ± 0.01 / 1000mm | ± 0.01 / 1000mm |

| Uburemere bukabije (T) | 8.5 | 11 | 13.5 | 16.5 | |

| Igikoresho c'ikinyamakuru | Ikinyamakuru igikoresho | ||||

Kugenzura Ubuziranenge

Buri mashini ya Bosman ihindurwamo laser interferometero yo mu Bwongereza RENISHAW yo mu Bwongereza, igenzura neza kandi ikishyura neza amakosa yo mu kibuga, gusubira inyuma, kumenya neza aho ihagaze, no guhagarikwa neza kugira ngo imashini ikore neza, ihagaze neza, kandi itunganyirizwe neza. . Ikizamini cy'umupira Buri mashini ikoresha igeragezwa ry'umupira woherejwe n’isosiyete yo mu Bwongereza RENISHAW kugira ngo ikosore neza uruziga nyarwo hamwe n’imashini ya geometrike, kandi ikore ubushakashatsi bwo gukata uruziga icyarimwe kugira ngo imashini ya 3D ikoreshwe neza kandi izenguruke.

Mbere & Nyuma ya Serivisi

1) Mbere yumurimo

Binyuze mu kwiga icyifuzo namakuru akenewe kubakiriya noneho ibitekerezo kuri injeniyeri zacu, itsinda rya tekinike rya Bossman rishinzwe itumanaho rya tekinike hamwe nabakiriya no gutegura ibisubizo, rifasha abakiriya guhitamo igisubizo kiboneye cyimashini hamwe nimashini zibereye.

2) Nyuma yumurimo

A.Imashini ifite garanti yumwaka umwe kandi yishyuwe kubungabunga ubuzima.

B.Mu gihe cya garanti yumwaka umwe nyuma yimashini igeze ku cyambu, BOSSMAN izatanga serivisi zokubungabunga kandi ku gihe ku makosa atandukanye atakozwe n'abantu ku mashini, kandi asimbure ku gihe cyose ubwoko bw’ibice byangiritse bitakozwe n'abantu ku buntu ishinzwe. Kunanirwa mugihe cya garanti bigomba gusanwa kubiciro bikwiye.

C. Inkunga ya tekiniki mumasaha 24 kumurongo, TM, Skype, E-imeri, gukemura ibibazo bijyanye mugihe. niba bidashobora gukemurwa, BOSSMAN izahita itegura ko injeniyeri nyuma yo kugurisha igera aho ikosorwa, umuguzi akeneye kwishyura VISA, amatike yindege nicumbi.

Urubuga rwisosiyete