BOSM-1601 Kurwanya-Umutwe Kurambura Imashini

1. Gukoresha ibikoresho

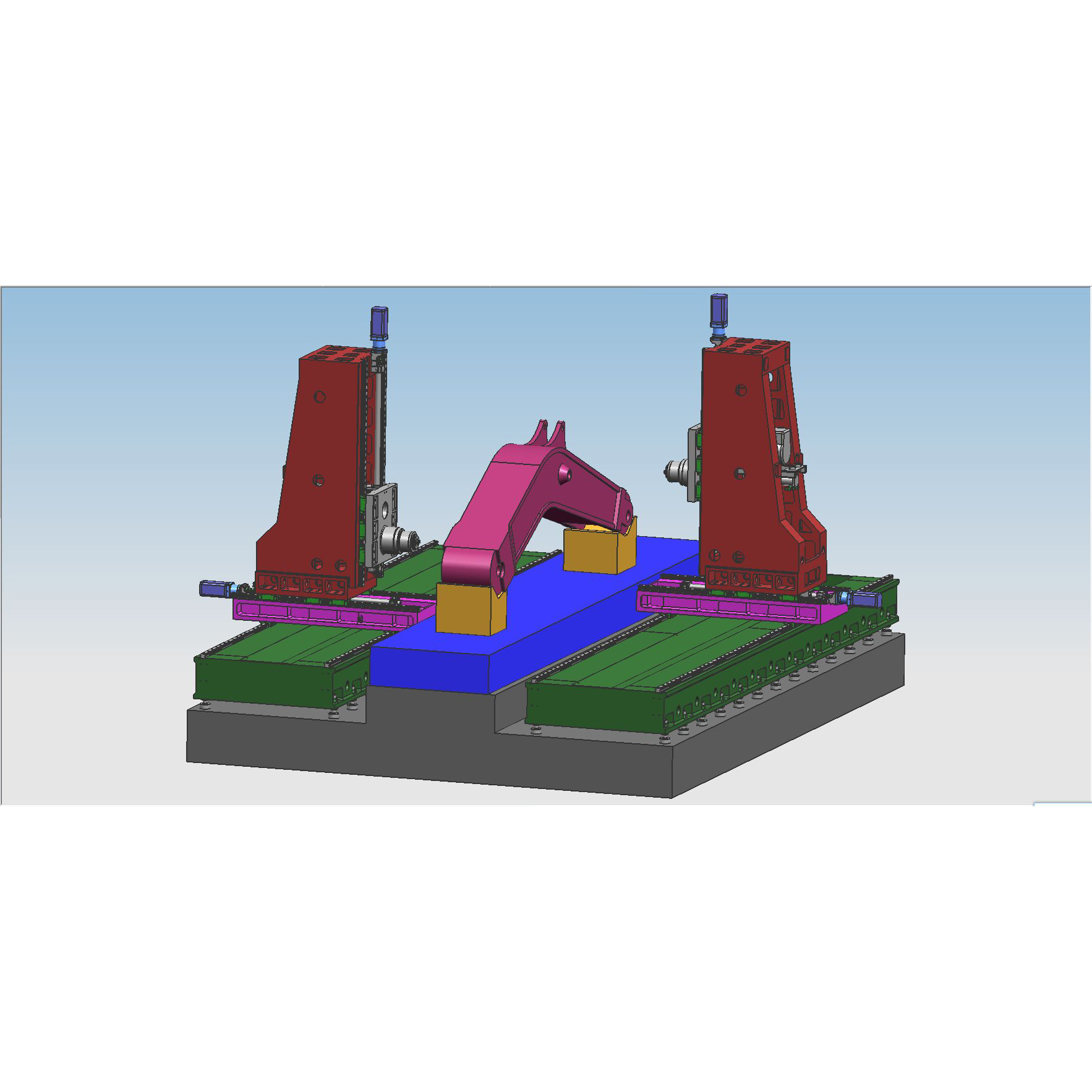

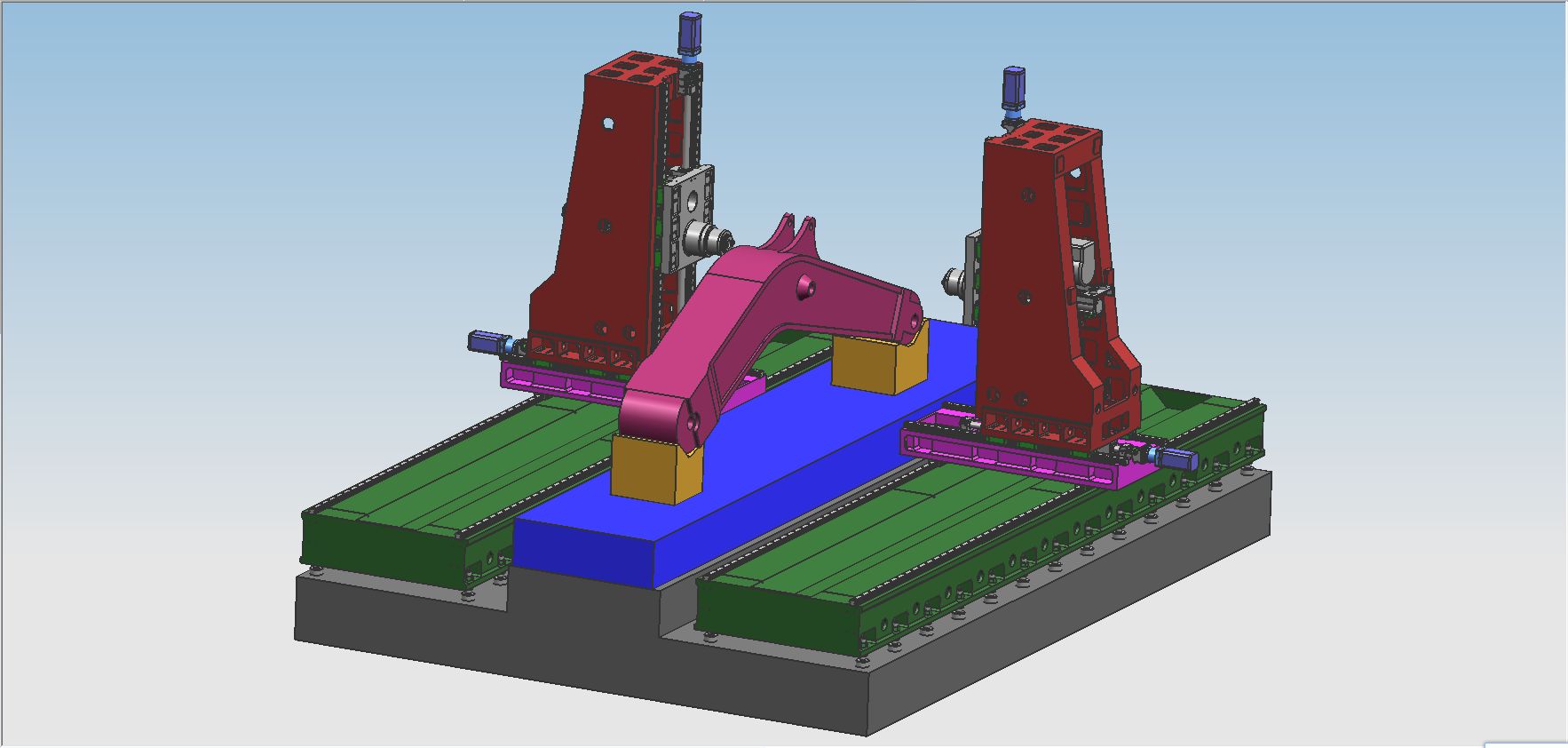

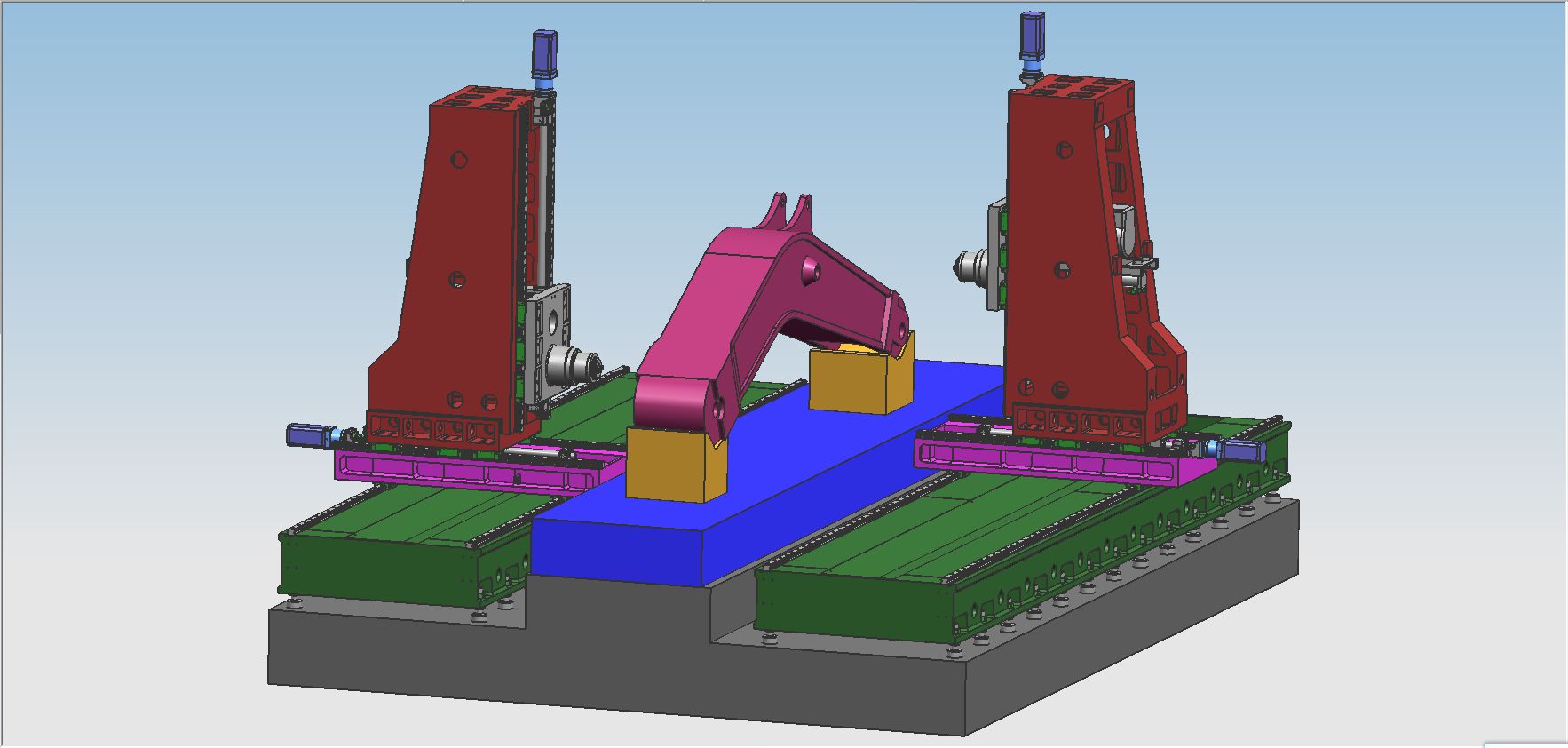

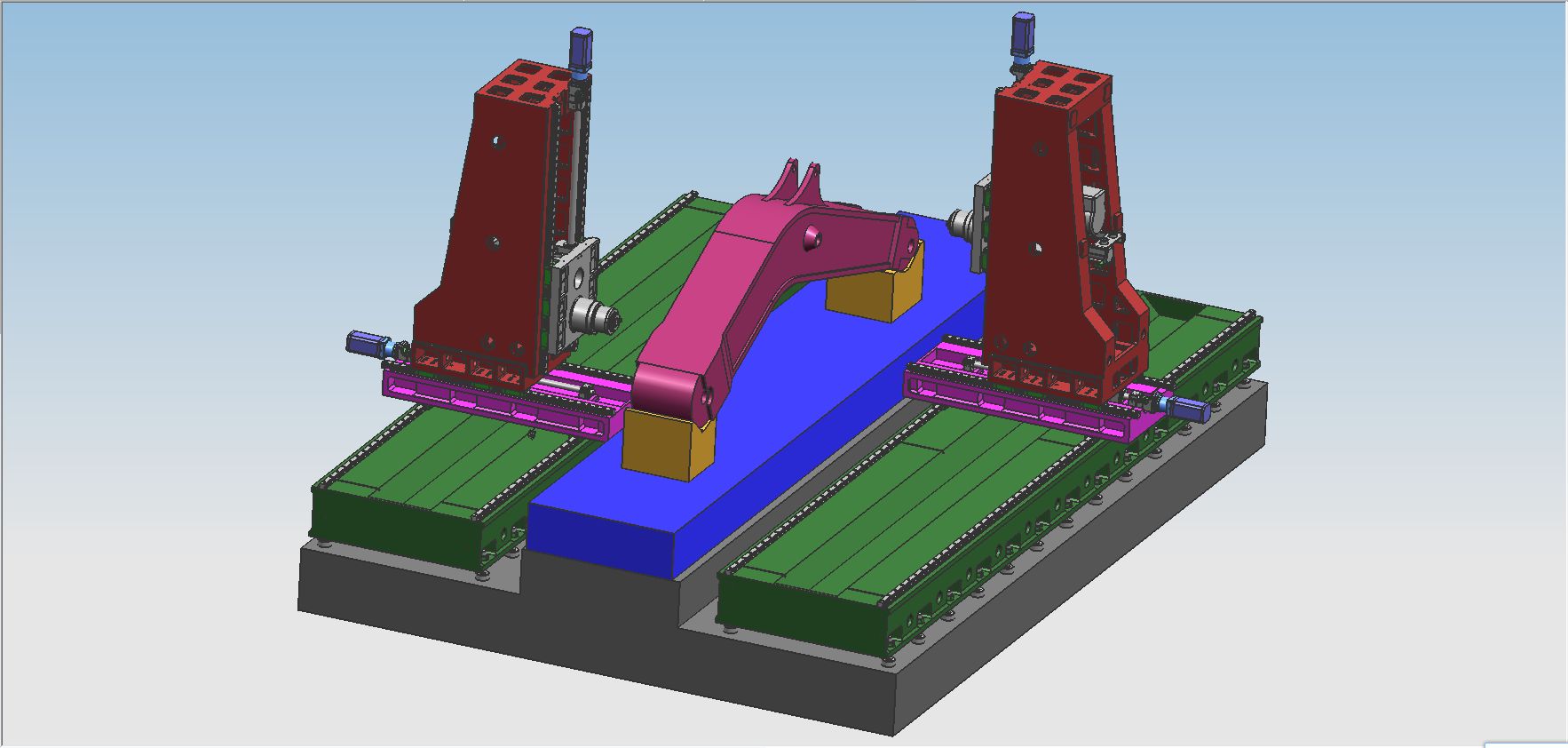

Imashini ya BOSM-1601 igizwe numubare wububiko bugendanwa inkingi ebyiri-inkingi umutwe-ku-mutwe-kurambirana no gusya ni Imashini idasanzwe yimirimo ikomatanya yimashini zubaka. Imashini ifite inkingi zidasanzwe zimukanwa hamwe nibice bibiri byintama zitambitse, zishobora kumenya Gucukura, gusya, kurambirana no gutunganya ikindi gice cyurwego rwimikorere ya stroke, igihangano gishobora gutunganyirizwa icyarimwe icyarimwe (ntakeneye icyiciro cya kabiri clamping), kwihuta kwipakurura no gupakurura umuvuduko, umuvuduko wihuse, gutunganya neza no gutunganya neza.

2. Ibice byingenzi bigize Imashini

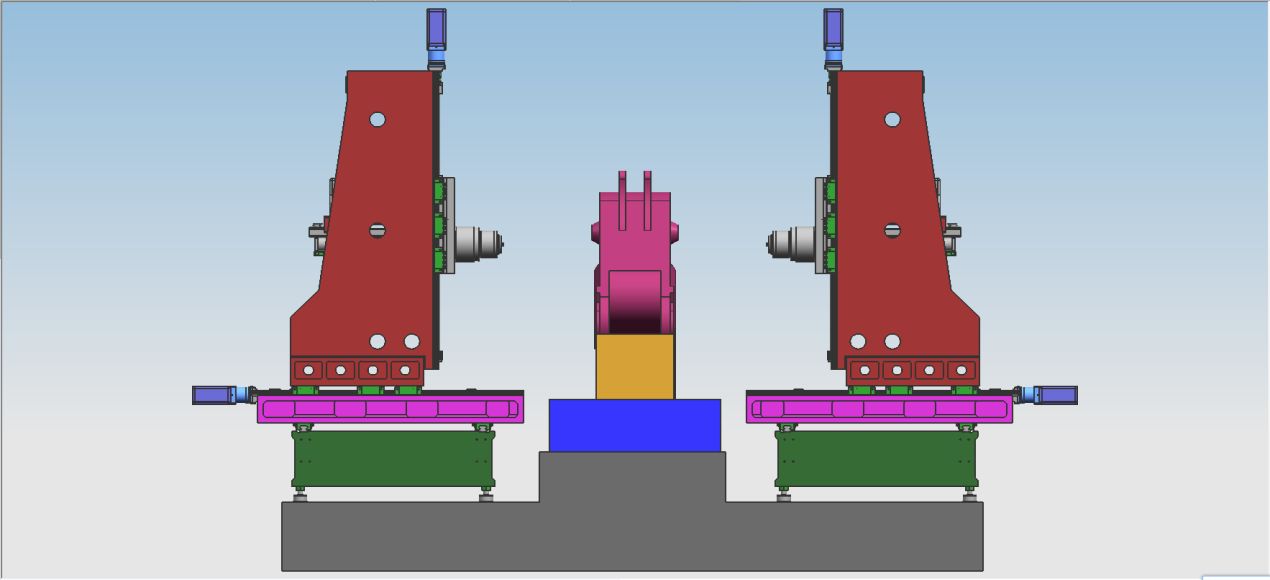

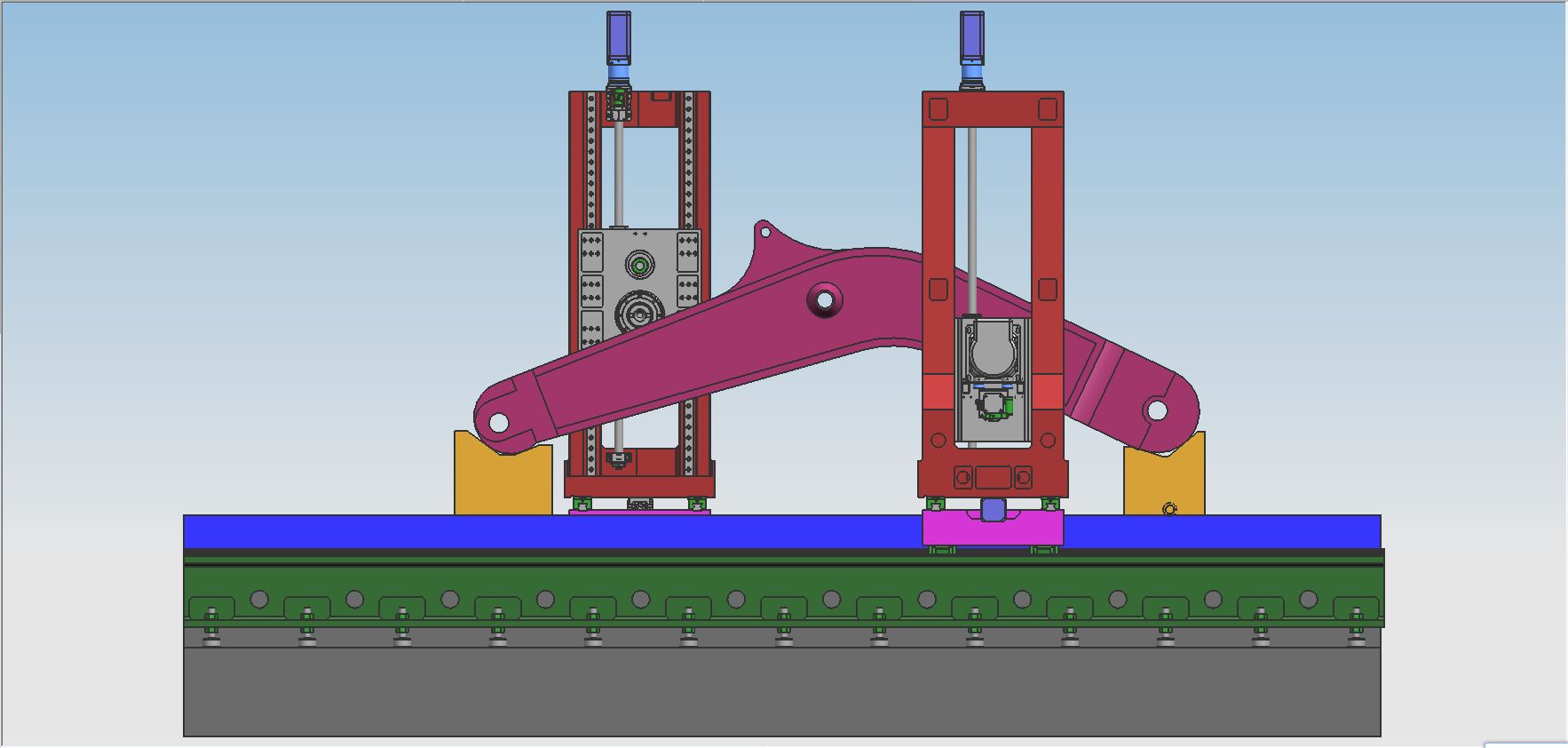

Uburiri, intebe yakazi, inkingi zi buryo n’iburyo, imirishyo, indogobe, impfizi n’ibindi bice binini byose bikozwe mu kubumba umucanga wa resin, icyuma cyiza cyo mu rwego rwo hejuru cyuma 250, guterana mu mwobo ushyushye → kunyeganyega gusaza → itanura rishyushye → guhinda umusaza → gutunganya nabi → Vibration gusaza → itanura rishyushye annealing → vibrasiya gusaza → kurangiza, kurandura burundu imihangayiko mibi yibice, kandi ukomeze imikorere yibice bihamye. Imashini ifite imirimo nko gusya, kurambirana, gucukura, kubara, gukanda, nibindi, kandi uburyo bwo gukonjesha ibikoresho ni ugukonjesha hanze, Imashini irimo amashoka 6 yo kugaburira, ashobora kumenya guhuza 4-axis hamwe na 6-axis imwe-imwe. Hano hari imitwe 2 yingufu. Icyerekezo cya axial ya Machine hamwe numutwe wimbaraga byerekanwe mumashusho hepfo.

2.1Imiterere nyamukuru yikiguzi cyo kugaburira igice

2.1.1 X1 / X2 umurongo:Inkingi isubirana igihe kirekire kuruhande rwa gari ya moshi iyobora uburiri buteganijwe.

Ikwirakwizwa rya X-axis: Itwarwa kandi ikagenzurwa na moteri ya AC servo, kugabanya umubumbe mwinshi-bigabanya umubumbe utwara inkingi zombi kugirango ugendere kumurongo X-unyuze mumupira woherejwe.

Imiyoboro ya gari ya moshi: Imirongo ibiri-ikomeye-yuzuye neza umurongo uyobora umurongo ushyizwe hejuru. Urwego rusobanutse rwumupira wumupira woherejwe ni C5.

2.1.2 Y1 / Y2 umurongo:Imbaraga zirambirana no gusya imitwe I, II hamwe ninkingi zabo byashyizwe kumurongo wimbaraga-shingiro zifatizo ziyobora kumpande zombi, kandi bigasubiranamo kumurongo wibanze shingiro kumurongo wa Y1 na Y2. Moteri ya AC servo ikoreshwa mugutwara no kugenzura imipira yohereza imipira, gukurura indogobe kugirango yimuke, no kumenya umurongo ugana kuri Y axis.

Ifishi ya gari ya moshi: 4 umurongo uyobora umurongo + umupira wamaguru. Urwego rwukuri rwumupira wumupira muburyo bwo kohereza ni C5, kandi igice cyafunzwe-gifunga kugenzura.

2.1.3 Z1 / Z2 umurongo:Kurambirana no gusya imitwe I, II hamwe nintebe zabo zinyerera zashyizwe muburyo buhagaritse kumpera yimbere yinkingi kumpande zombi, hanyuma bigasubirana kumashoka ya Z1 na Z2 hejuru no hepfo kumurongo wubuyobozi.

Ikwirakwizwa rya Z1-axis: moteri ya AC servo ikoreshwa mugutwara no kugenzura neza-kugabanya umubumbe mwinshi hamwe no gukwirakwiza imipira, hamwe na ya mpfizi y'intama itwarwa kugirango igende neza kuri Z-axis.

Ifishi ya gari ya moshi: 2 umurongo wa gari ya moshi uyobora. Urwego rwukuri rwumupira wumupira woherejwe ni C5.

2.2 Gukuraho Chip no gukonjesha

Hano hari imiyoboro ya chip iringaniye kandi iringaniye yashyizwe kumpande zombi munsi yumwanya wakazi, kandi chip irashobora guhita igezwa kuri chip convoyeur ikarangira binyuze mubyiciro bibiri byizunguruka hamwe nuruhererekane kugirango habeho umusaruro uteganijwe. Hano hari pompe ikonjesha mu kigega gikonjesha cya chip convoyeur, gishobora gukoreshwa mugukonjesha hanze igikoresho kugirango harebwe imikorere nubuzima bwa serivise, kandi ibicurane birashobora gukoreshwa.

3. Sisitemu yuzuye yo kugenzura imibare:

3.1. Hamwe nimikorere ya chip yameneka, chip yameneka hamwe na chip yameneka irashobora gushirwa kumurongo wimashini.

3.2. Hamwe nibikoresho byo guterura ibikoresho, intera yo guterura igikoresho irashobora gushirwa kumurongo wimashini. Iyo intera igeze, igikoresho kizamurwa vuba, hanyuma imitwe ikajugunywa kure, hanyuma igahita yoherezwa hejuru yubucukuzi hanyuma igahita ihinduka akazi.

3.3. Igenzura rikorwa hagati yisanduku hamwe nintoki zifatanije zifata sisitemu yo kugenzura imibare kandi ifite ibikoresho bya USB hamwe na LCD y'amazi ya kirisiti. Kugirango byorohereze porogaramu, kubika, kwerekana no gutumanaho, interineti ikora ifite imikorere nkibiganiro byabantu-imashini, indishyi zamakosa, hamwe no gutabaza byikora.

3.4. Ibikoresho bifite umurimo wo kureba no kongera kugenzura aho umwobo mbere yo gutunganya, kandi imikorere iroroshye cyane.

4. Amavuta yo kwisiga

Imashini isobanutse neza umurongo wa gari ya moshi, imipira yumupira wuzuye hamwe nibindi byerekezo bihanitse byerekanwe hamwe na sisitemu yo gusiga amavuta. Pompe yamavuta yo kwisiga isohora amavuta yumuvuduko, kandi urugereko rwamavuta rwinshi rwinjira mumavuta. Nyuma yicyumba cyamavuta cyuzuyemo amavuta, mugihe umuvuduko wa sisitemu uzamutse ugera kuri 1.4-1.75Mpa, icyerekezo cyumuvuduko muri sisitemu kirafungwa, pompe irahagarara, na valve ipakurura ipakurura icyarimwe. Iyo umuvuduko wamavuta mumuhanda ugabanutse munsi ya 0.2Mpa, amavuta yo kwisiga atangira kuzuza amavuta hanyuma arangiza kuzuza amavuta. Bitewe n’amavuta yukuri yo gutera inshinge zingana no kumenya umuvuduko wa sisitemu, itangwa ryamavuta ryizewe, ryemeza ko hejuru ya buri firime ya kinematike, hagabanywa ubushyamirane no kwambara, no gukumira ibyangiritse kuri imiterere y'imbere iterwa n'ubushyuhe bukabije. , kugirango tumenye neza nubuzima bwimashini. Ugereranije no kunyerera kuyobora gari ya moshi, kuzenguruka umurongo wa gari ya moshi ikoreshwa muri iyi Imashini ifite urukurikirane rwibyiza:

Mot Kwiyunvikana kwinshi, coefficient de fraisement ya gari ya moshi iyobora ni nto, 0.0025-0.01 gusa, kandi imbaraga zo gutwara ziragabanuka cyane, bihwanye na 1 yimashini zisanzwe. / 10.

Itandukaniro riri hagati yo guterana imbaraga hamwe na static ni ntoya cyane, kandi imikorere yo gukurikirana ni nziza, ni ukuvuga ko intera iri hagati yikimenyetso cyo gutwara no gukora imashini ari ngufi cyane, ifasha kunoza umuvuduko wo gusubiza no kumva neza sisitemu yo kugenzura imibare.③Birakwiriye kwihuta cyane kumurongo, kandi umuvuduko wako uhita wikubye inshuro 10 ugereranije nu kunyerera. Can Irashobora gutahura urujya n'uruza no kunoza urujya n'uruza rwa sisitemu ya mashini. RoduByakozwe nababikora babigize umwuga, bifite ibisobanuro bihanitse, bihindagurika neza kandi byoroshye kubungabunga.

5. Imashini ikoresha ibidukikije:

5.1. Ibidukikije bisabwa kugirango ukoreshe ibikoresho

Kugumana urwego ruhoraho rwubushyuhe bwibidukikije ni ikintu cyingenzi cyo gutunganya neza.

.

(2) Kugirango ugumane neza neza Imashini murwego rwagenwe, ubushyuhe bwiza bwibidukikije busabwa kuba 15 ° C kugeza kuri 25 ° C, nubushyuhe bwubushyuhe

Ntugomba kurenza ± 2 ° C / 24h.

5.2 Umuyagankuba w'amashanyarazi: icyiciro 3, 380V, murwego rwa 10% ihindagurika rya voltage, inshuro zitanga amashanyarazi: 50HZ.

5.3 Niba voltage mumurimo ikoreramo idahindagurika, Imashini igomba kuba ifite amashanyarazi ahamye kugirango imikorere isanzwe yimashini.

5.4 Imashini igomba kuba ifite ishingiro ryizewe: insinga yo hasi ni insinga y'umuringa, diameter y'insinga ntigomba kuba munsi ya 10mm², kandi kurwanya ubutaka ni bito muri 4 oms.

5.5 Kugirango hamenyekane imikorere isanzwe yibikoresho, niba umwuka wugarije isoko yikirere udashobora kuzuza ibisabwa nisoko ryikirere, ugomba gushyirwa kuri Machine.

Ongeramo igikoresho cyogusukura ikirere (dehumidification, degreasing, filter) mbere yumwuka.

5.6 Shyira ibikoresho kure yizuba ryizuba, kunyeganyega nubushyuhe, ibyuma bitanga amashanyarazi menshi, imashini zogosha amashanyarazi, nibindi, kugirango wirinde gutsindwa kwimashini cyangwa gutakaza neza kwimashini.

6. Ibipimo bya tekiniki

| Icyitegererezo | 1601 | |

| Ingano yakazi | Uburebure × ubugari × uburebure (mm) | 16000 × 1000 × 1500 |

| Imashini ibiryo byinshi | Ubugari (mm) | 1300 |

| Ingano yakazi | Uburebure X Ubugari (mm) | 16000 * 1000 |

| Urugendo | Inkingi isubira inyuma (mm) | 1600 |

| Kuzunguruka hejuru | Urugendo rwo hejuru no kumanuka (mm) | 1500 |

| Uburebure kuva spindle center kugeza kumeza yindege | 100-1600mm | |

| Horizontal imbaraga nyinshi zizunguruka imbaraga umutwe umwe kabiri | Umubare (2) | 2 |

| Kanda | BT50 | |

| Broach | Automatic broaching, intoki guhindura ibikoresho | |

| Gukata diameter (mm) | ≤Φ200 | |

| Kanda diameter (mm) | M3-M30 | |

| Umuvuduko ukabije (r / min) | 30 ~ 3000 | |

| Servo izunguruka moteri (kw) | 30 * 2 | |

|

| Urugendo rwibumoso n iburyo hagati yimpande ebyiri | 400-1600mm |

| Urugendo rw'ibumoso n'iburyo bw'inkingi ebyiri (mm) | 600 buri umwe | |

| Gukonjesha ibikoresho | Gukonjesha imbere, gukonjesha hanze | |

| Imyanya ibiri ihagaze neza | 300mm | ± 0.032 |

| Bi-icyerekezo gisubiramo imyanya nyayo | 300mm | ± 0.025 |

| Ibipimo by'imashini | Uburebure × ubugari × uburebure (mm) | Ukurikije ibishushanyo (niba hari impinduka mubikorwa byo gushushanya, tuzakumenyesha) |

| Uburemere bukabije (t) | 72T | |