BOSM -6010 Kurwanya-Umutwe Boring Imashini

1. Gukoresha imashini:

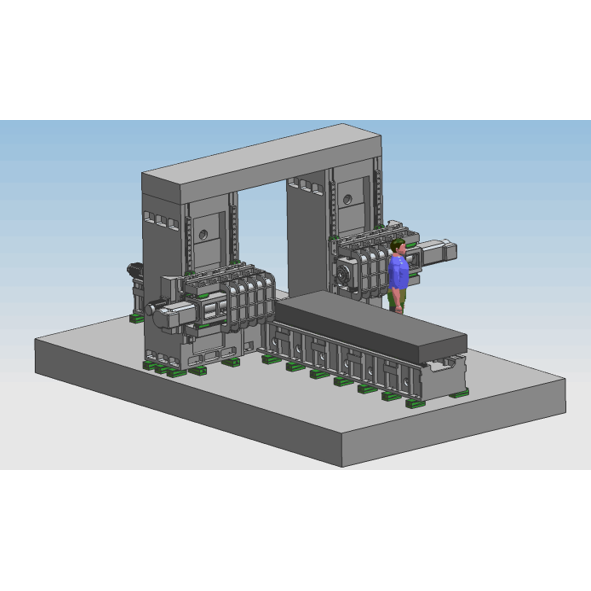

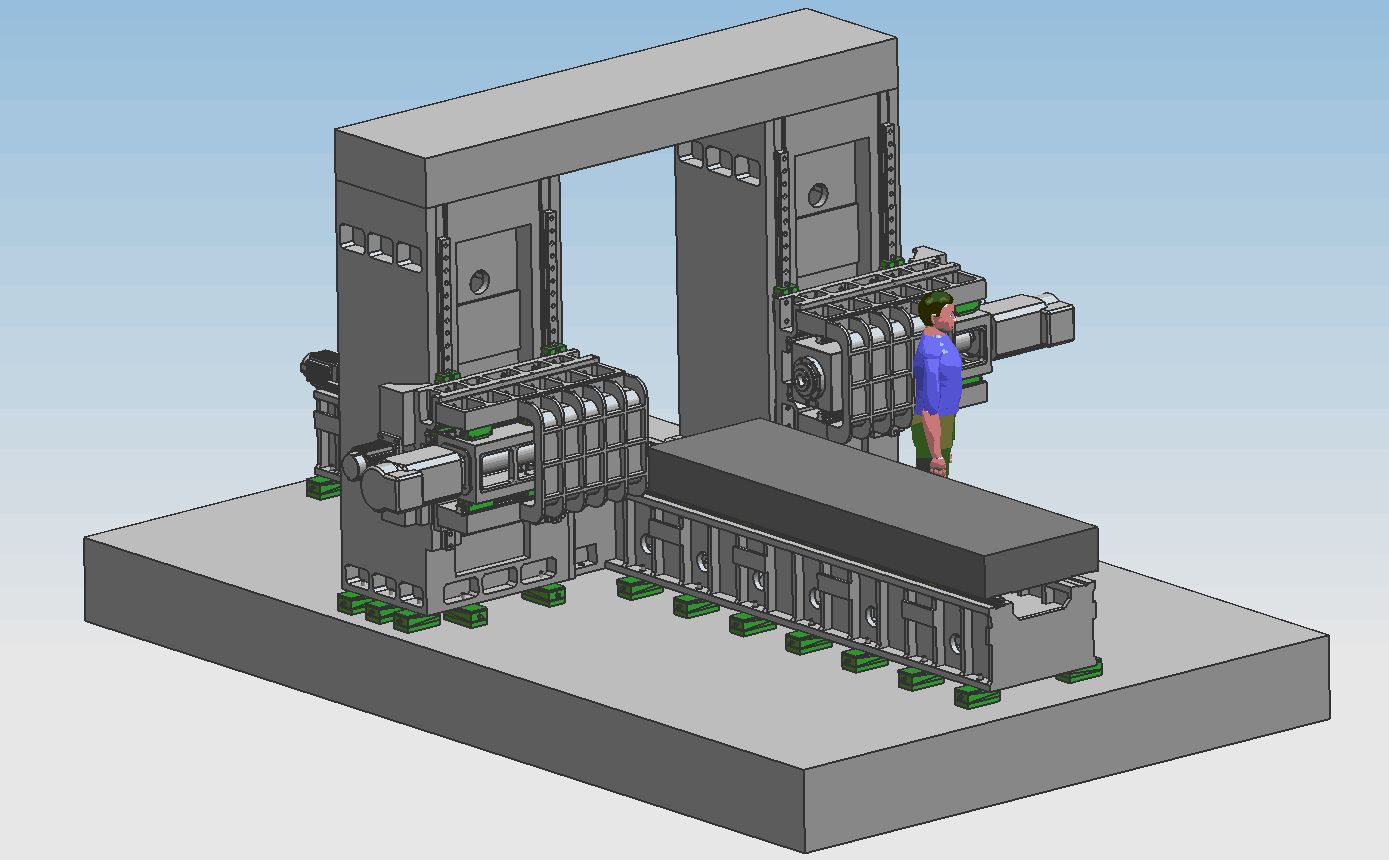

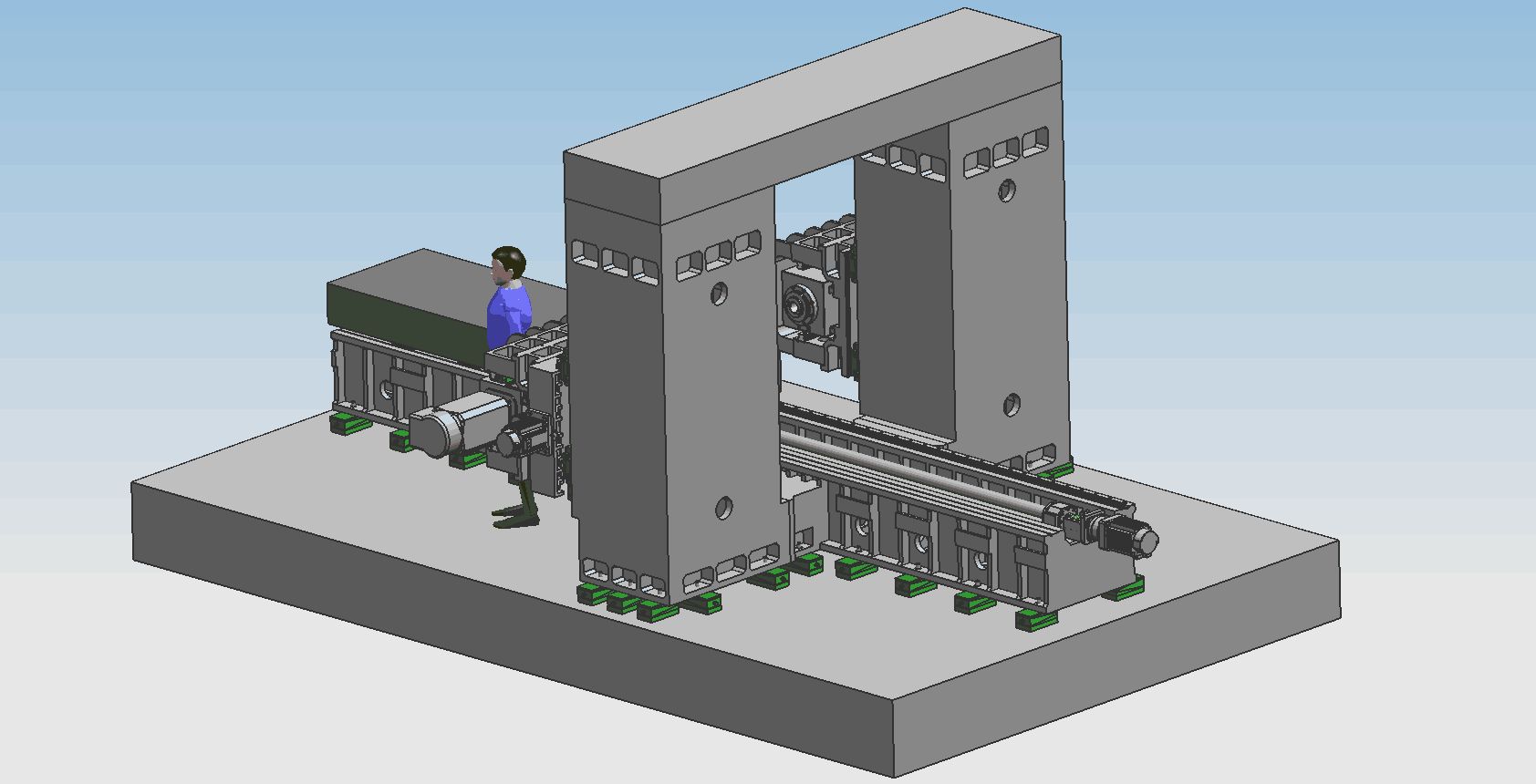

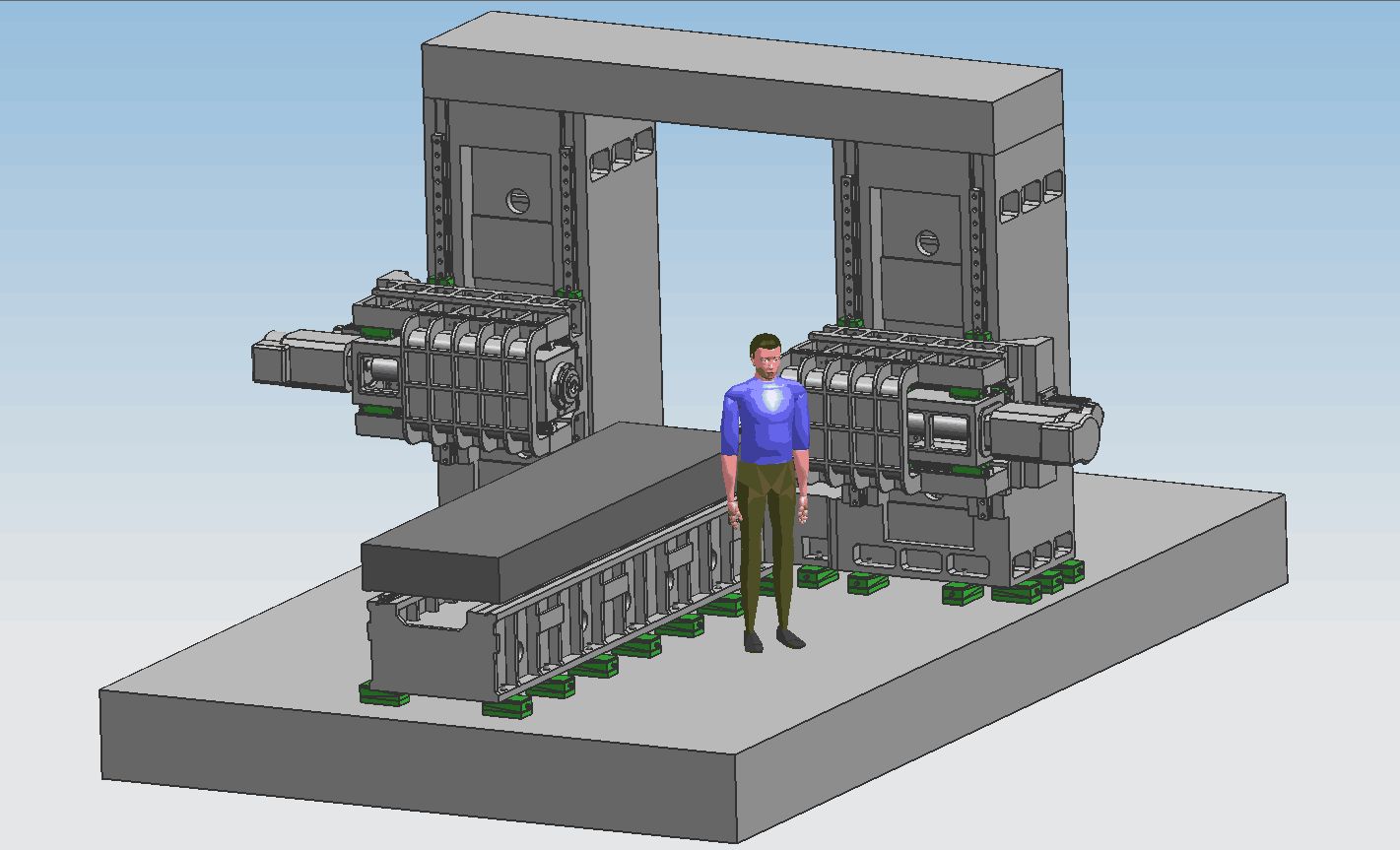

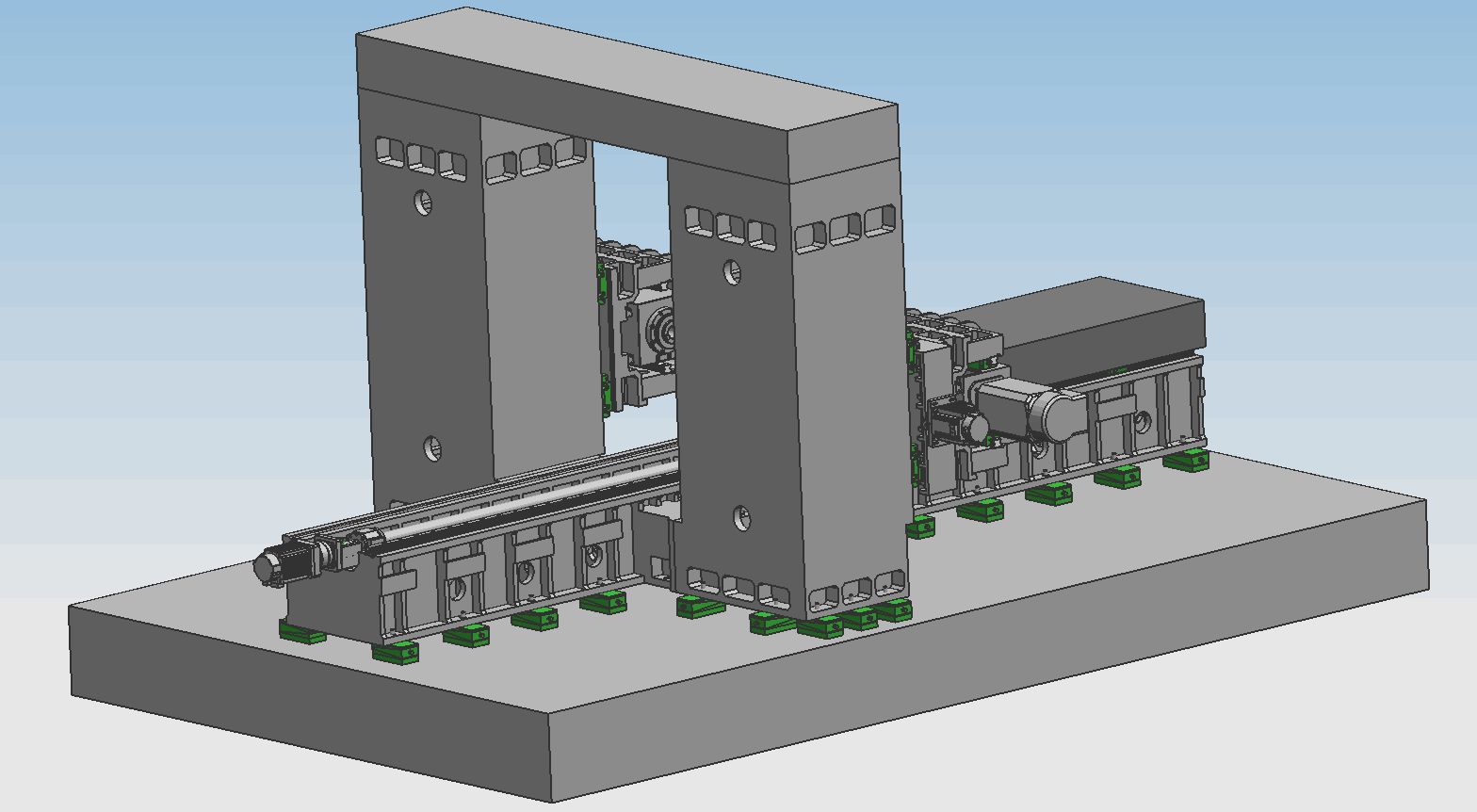

BOSM- 6000 * 1000 itunganijwe neza-CNC gantry kabiri-inkingi umutwe-ku-mutwe kurambirana no gusya ni igikoresho cyimashini idasanzwe yo gutunganya amaboko / inkoni.Umusego, urashobora gutahura uburyo bwihuse bwibikorwa byakazi, igihangano gishobora gucukurwa, gusya, no kurambirwa murwego rukomeye rwa stroke, igihangano gishobora gutunganyirizwa icyarimwe icyarimwe (nta mpamvu yo gufatira hamwe), umuvuduko wo gupakira no gupakurura ni byihuse, umwanya wihuta urihuta, kandi gutunganya neza ni hejuru.Uburyo bwiza bwo gutunganya neza.

2.Imashini imiterereibiranga:

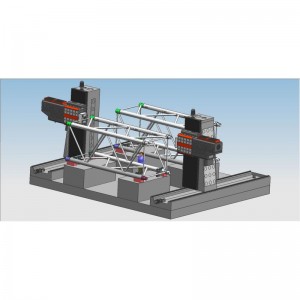

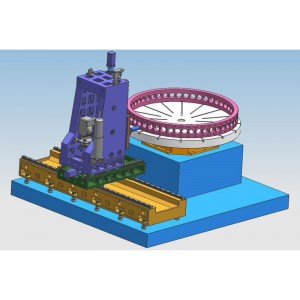

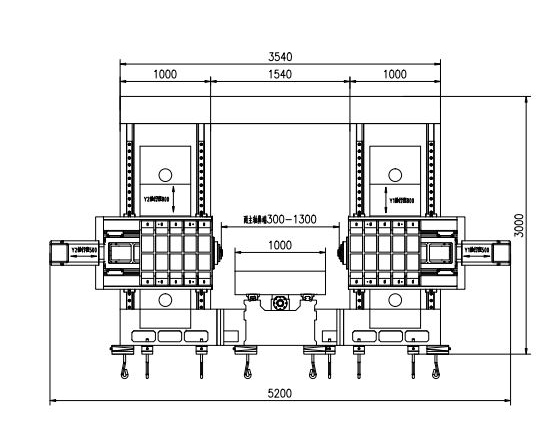

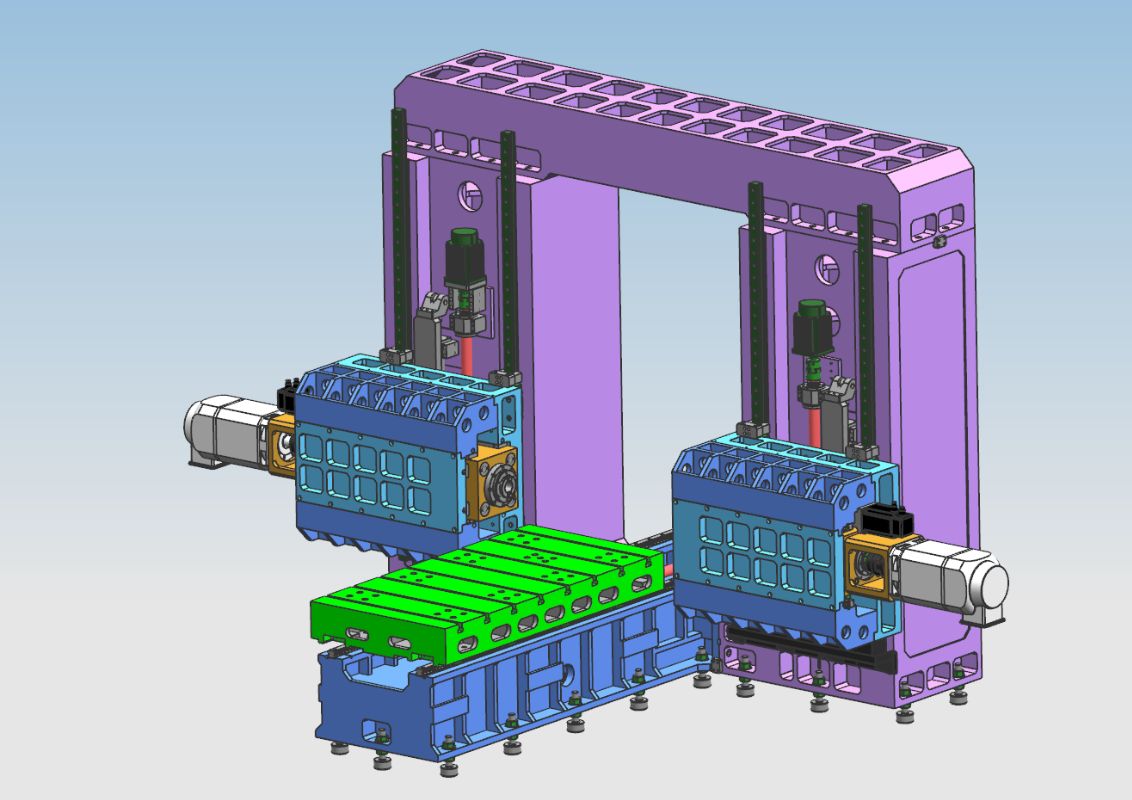

Ibice byingenzi bigize igikoresho cyimashini: uburiri, intebe yakazi, ibumoso n iburyo, inkingi, gantry ihuza imirishyo, amatandiko, impfizi, impfizi, nibindi, ibice binini bikozwe mubibumbano byumucanga, ibyuma byiza byumuhondo byujuje ubuziranenge 250, byometse mubushuhe umwobo wumucanga → kunyeganyega gusaza treatment kuvura ubushyuhe bwa Furnace annealing → vibrasiya gusaza → gukora imashini → vibrasiya gusaza → itanura rishyushye annealing → vibrasiya gusaza → kurangiza, gukuraho burundu imihangayiko mibi yibice, kandi bikomeza imikorere yibice bihamye.Uburiri butajegajega, ibumoso n'iburyo inkingi, gantry, hamwe n'intebe y'akazi;Ifite imirimo yo gusya, kurambirana, gucukura, kubara, gukanda, nibindi. Uburyo bwo gukonjesha ibikoresho ni gukonjesha hanze.Igikoresho cyimashini kirimo ibiryo 5 byo kugaburira, bishobora kumenya 4-axis ihuza hamwe na 5-axis imwe-igikorwa.Hano hari imitwe 2 yingufu.Umurongo wigikoresho cya machine numutwe wimbaraga byerekanwe kumashusho hepfo.X

2.1.Imiterere nyamukuru yikiguzi cyo kugaburira igice

2.1.1.X-axis:Urupapuro rwakazi rusubirana kuruhande rwa gari ya moshi iyobora uburiri buteganijwe.

X.

Imiyoboro ya gari ya moshi: shyira ibice bibiri-bikomeye-byuzuye umurongo uyobora umurongo.

2.1.2 Z1 umurongo:Imbaraga zumutwe hamwe nigitereko byashyizwe muburyo bwimbere bwinkingi, hanyuma bigasubirana hejuru no hepfo kumurongo wa gari ya moshi.

Ikwirakwizwa rya Z1-axis: moteri ya AC servo hamwe nuruziga rukoreshwa mugutwara umupira wumupira kugirango utware indogobe kugirango umenye Z- axis umurongo ugenda.

2.1.3 Z2 umurongo:Imbaraga zumutwe hamwe nigitereko byashyizwe muburyo bwimbere bwinkingi, hanyuma bigasubirana hejuru no hepfo kumurongo wa gari ya moshi.

Ikwirakwizwa rya Z2-axis: moteri ya AC servo hamwe nuruziga rukoreshwa mugutwara umupira wumupira kugirango utware indogobe kugirango umenye Z- axis umurongo.

2.1.4 Y1 umurongo:Imbaraga z'umutwe w'amashanyarazi zashyizwe mu buryo buhagaritse ku ruhande rw'imbere rw'inkingi y'iburyo, kandi igasubiza ibumoso n'iburyo ku nkingi iyobora gari ya moshi.

Y1-axis yoherejwe: moteri ya AC servo hiyongereyeho kugabanya umubumbe mwinshi-bigabanya gutwara impfizi y'intama kugirango inyure mumupira kugirango umenye umurongo wa Y1- axis

2.1.5 Y2 umurongo:Imbaraga z'umutwe w'igitereko zashyizwe muburyo buhagaritse kuruhande rwimbere yinkingi iburyo, kandi bigasubiza ibumoso niburyo kuruhande rwa gari ya moshi.

Y2-axis yohereza: moteri ya AC servo hiyongereyeho kugabanya umubumbe wuzuye-mubumbe ukoreshwa mugutwara impfizi y'intama kugirango inyure mumupira kugirango umenye icyerekezo cya Y2- axis.

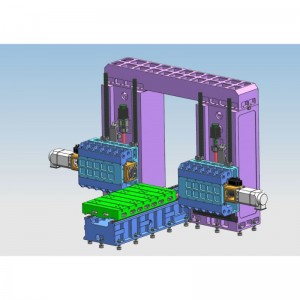

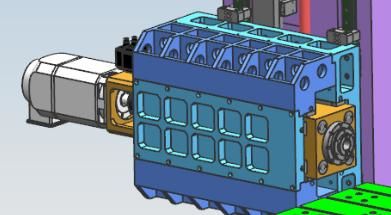

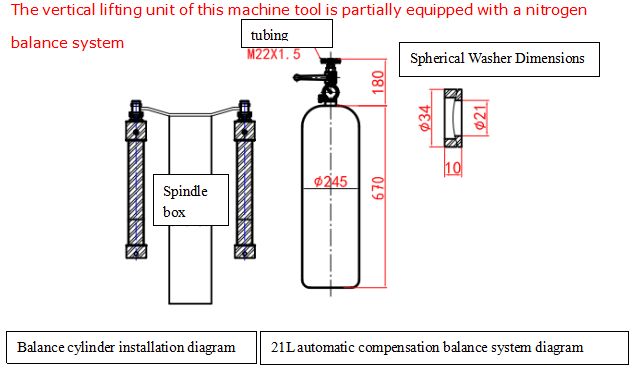

2.2.Icyerekezo kigenda cyumutwe wogucukura no gusya (harimo numutwe wamashanyarazi 1 na 2) bifata imiterere yintama ya kare, uburyo bwa gari ya moshi igezweho igezweho, inzira ya gari ya moshi ikikijwe ninkunga ikomeye, inzira ya gari ya moshi 4 ibice bibiri birayoborwa, kandi ikinyabiziga gikoresha moteri ya AC servo Gutwara umukandara wa syncronous (i = 2) hamwe nu muyoboro wuzuye wa ball ball, umutwe wimbaraga ufata moteri ya servo kugirango wihute unyuze mumukandara wa syncron hamwe ninziga ya syncron, iyobowe ninshingano ziremereye cyane kuyobora inzira ya gari ya moshi, kandi itwara umupira uhagaze kugirango uzunguruke, umenye umutwe wimbaraga Kora hejuru no hepfo ugenda uhagaritse, kandi ushyizwemo na azote iringaniza kugirango ugabanye ubushobozi bwo gutwara umutwe wimashini kuri screw na moteri ya servo.Moteri Z-axis ifite imikorere ya feri yikora.Mugihe cyo kunanirwa kwamashanyarazi, feri yikora izajya ifata moteri ya moteri., ku buryo idashobora kuzunguruka.Iyo ukora, mugihe imyitozo ya biti idakora kumurimo, izagaburira vuba;iyo imyitozo ya biti ikora kumurimo, izahita ihindura ibiryo byakazi.Iyo imyitozo ya biti yinjiye mubikorwa, izahita ihinduka kuri rewind yihuse;mugihe iherezo ryimyitozo biturutse kumurimo hanyuma ikagera kumwanya washyizweho, imbonerahamwe izimukira kumwanya ukurikira kugirango umenye kuzenguruka byikora.Umutwe w'amashanyarazi ukoresha guhuza insinga na gari ya moshi ikomeye, ntabwo itanga gusa umuvuduko wibikoresho, ahubwo binongera cyane ubukana bwibikoresho.Kandi irashobora kumenya imikorere yo gucukura umwobo uhumye, gusya, gutondagura, kumena chip, kuvanaho chip byikora, nibindi, bitezimbere umusaruro wumurimo.

(ibumoso bw'imbaraga)

2.3.Gukuraho Chip no gukonjesha

Hano hari imiyoboro ihanamye kandi iringaniye yashizwe kumpande zombi munsi yumwanya wakazi, kandi chip zirashobora guhita zisohorwa kuri chip convoyeur zirangije binyuze mubyiciro bibiri byizunguruka hamwe nu munyururu kugirango tumenye umusaruro uteganijwe.Hano hari pompe ikonjesha mu kigega gikonjesha cya chip convoyeur, gishobora gukoreshwa mugukonjesha hanze igikoresho kugirango hamenyekane imikorere yubucukuzi nubuzima bwa serivisi ya biti, kandi coolant irashobora gukoreshwa.

3.Sisitemu yuzuye yo kugenzura imibare:

3.1.Hamwe nimikorere ya chip yameneka, chip yameneka hamwe na chip yameneka irashobora gushirwa kumurongo wimashini.

3.2.Hamwe nimikorere yo guterura ibikoresho, kuzamura ibikoresho birashobora gushirwa kumurongo wimashini.Iyo gucukura bigeze kuri ubu burebure, biti ya myitozo irazamurwa vuba hejuru yakazi, hanyuma imitwe ikajugunywa kure, hanyuma ikoherezwa vuba yerekeza hejuru yubucukuzi hanyuma igahita ihinduka akazi.

3.3.Igikorwa gikomatanyije cyo kugenzura agasanduku hamwe nigikoresho gifata sisitemu yo kugenzura imibare kandi ifite ibikoresho bya USB hamwe na LCD ya kirisiti yerekana.Kugirango byorohereze porogaramu, kubika, kwerekana no gutumanaho, interineti ikora ifite imikorere nkibiganiro byabantu-imashini, indishyi zamakosa, hamwe no gutabaza byikora.

3.4.Ibikoresho bifite umurimo wo kureba no kongera kugenzura aho umwobo mbere yo gutunganya, kandi imikorere iroroshye cyane.

4.Amavuta yo kwisiga

Imashini igikoresho cyerekana neza umurongo wa gari ya moshi, imipira yumupira wuzuye hamwe nibindi byerekezo bihanitse byerekanwe hamwe na sisitemu yo gusiga amavuta.Pompe yamavuta yo kwisiga isohora amavuta yumuvuduko, kandi urugereko rwamavuta rwinshi rwinjira mumavuta.Nyuma yicyumba cyamavuta cyuzuyemo amavuta, mugihe umuvuduko wa sisitemu uzamutse ugera kuri 1.4-1.75Mpa, icyerekezo cyumuvuduko muri sisitemu kirafungwa, pompe irahagarara, na valve ipakurura ipakurura icyarimwe.Iyo umuvuduko wamavuta mumuhanda ugabanutse munsi ya 0.2Mpa, amavuta yo kwisiga atangira kuzuza amavuta hanyuma arangiza kuzuza amavuta.Bitewe n’amavuta yukuri yo gutera inshinge zingana no kumenya umuvuduko wa sisitemu, itangwa ryamavuta ryizewe, ryemeza ko hejuru ya buri firime ya kinematike, hagabanywa ubushyamirane no kwambara, no gukumira ibyangiritse kuri imiterere y'imbere iterwa n'ubushyuhe bukabije., kugirango tumenye neza nubuzima bwigikoresho cyimashini.Ugereranije nu kunyerera kuyobora gari ya moshi, kuzenguruka umurongo wa gari ya moshi ikoreshwa muri iki gikoresho cyimashini ifite urukurikirane rwibyiza:

SensitivityIcyerekezo cyimikorere ni kinini, coefficente yo guterana ya gari ya moshi iyobora ni nto, 0.0025 ~ 0.01 gusa, kandi imbaraga zo gutwara ziragabanuka cyane, bihwanye na 1/10 cyimashini zisanzwe.

Itandukaniro riri hagati yo guterana imbaraga hamwe na static ni ntoya cyane, kandi imikorere yo gukurikirana ni nziza, ni ukuvuga ko intera iri hagati yikimenyetso cyo gutwara no gukora imashini ari ngufi cyane, ifasha kunoza umuvuduko wo gusubiza no kumva neza sisitemu yo kugenzura imibare.

TBirakwiriye kwihuta cyane kumurongo, kandi umuvuduko wako uhita wikubye inshuro 10 kurenza iyo kunyerera.

Can Irashobora gutahura urujya n'uruza no kunoza urujya n'uruza rwa sisitemu ya mashini.

RoduByakozwe nababikora babigize umwuga, bifite ibisobanuro bihanitse, bihindagurika neza kandi byoroshye kubungabunga.

5.Imashini ikoresha ibidukikije:

Amashanyarazi: ibyiciro bitatu AC380V ± 10%, 50Hz ± 1 Ubushyuhe bwibidukikije: 0 ° ~ 45 °

Gatanu, ibyingenzi byingenzi bya tekiniki:

| icyitegererezo | BOSM4014 | |

| Ingano ntarengwa yo gutunganya | Uburebure × ubugari × uburebure (mm) 4000 × 1600 × 1000 | |

| Gantry ibiryo byinshi | Ubugari (mm) | 2300 |

| ingano yimeza | Uburebure X Ubugari (mm) | 4000 * 1400 |

|

Ubwoko bw'intama y'ubwoko butambitse imbaraga umutwe umwe kabiri

| Umubare (2) | 2 |

| Kanda | BT50 | |

| Gucukura diameter (mm) | Φ2-Φ60 | |

| Kanda diameter (mm) | M3-M30 | |

| Gusya disiki ya diameter (mm) | 300 | |

| Umuvuduko ukabije (r / min) | 30 ~ 6000 | |

| Servo izunguruka moteri (kw) | 37 | |

| Kuzenguruka izuru intera iri hagati yimeza (mm) | 650-1150 | |

| Ibumoso n'iburyo bw'intama imwe (mm) | 500 | |

| Intera iri hagati ya ya mpfizi y'intama n'indege y'ameza (mm) | 200-1400 | |

| Hejuru no hepfo y'intama y'intama (mm) | 1200 | |

| Gusubiramo | 300mm * 300mm | ± 0.02 |

| Ibipimo by'imashini | Uburebure × ubugari × uburebure (mm) | ukurikije ibishushanyo |

| Uburemere bukabije (t) | (hafi.) 36 | |

Ibipimo byavuzwe haruguru nibishushanyo mbonera.Mu gishushanyo nyirizina, hashobora kubaho impinduka ukurikije ibisabwa byo gutunganya igihangano cyakazi hamwe nibisabwa kugirango igikoresho gikorwe, kugirango uhuze ibisabwa nibice bitunganya uruganda rwawe.